Ankleshwar Gidc, Gujarat

- GST NO. : 24ACNPC1767D1ZW

Mobile : View Mobile Number

| Business Type | Manufacturer, Exporter |

| Number Of Flower | Automatic |

| Material | Mild Steel |

| Packaging Type | Sliver |

| Click to view more | |

Product Details

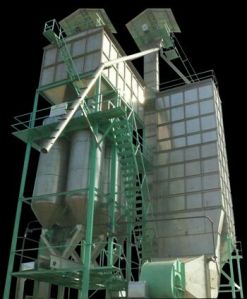

Kettle Reboiler Type Heat Exchanger is a retaining wall or overflow weir separating the tube bundle from the reboiler section where the residual reboiled liquid called the bottoms product, Kettle Reboiler Type Heat Exchanger bundle is kept covered with liquid.Kettle reboilers are reliable in that they can handle high vaporization of up to 80 percent and are easy to maintain. The liquid from the bottom of the tower flows through the tube bundle and exits as condensate. Kettle reboilers are very simple and reliable. Kettle Reboiler Type Heat Exchanger may require pumping of the column bottoms liquid into the kettle, there may be sufficient liquid head to deliver the liquid into the reboiler. Kettle Reboiler Type Heat Exchanger reboiler type, steam flows through the tube bundle and exits as condensate. The liquid from the bottom of the tower, commonly called the bottoms, flows through the shell side. A restraining device controls the liquid level over the bundle. The high level of vaporization makes it prone to fouling, and these reboilers are expensive due to their large shell size and maintenance.

Specifications :

- Kettle reboilers are heat exchangers typically used to provide heat to the bottom of industrial distillation columns.

- In a typical classical distillation column, all the vapor driving the separation comes from the reboiler.

- The reboiler receives a liquid stream from the column bottom and may partially or completely vaporize that stream. Steam usually provides heat required for the vaporization.

- Kettle reboilers the liquid from the bottom of a distillation column to generate vapors which are returned to the column to drive the distillation separation. Proper reboiler operation is effective distillation.

- The reboiler receives a liquid stream from the column bottom and may partially, completely vaporize that stream.

- Steam usually provides heat required for the vaporization.

Looking for "Kettle Reboiler Heat Exchanger" ?

Explore More Products

Our Blogs