Ankleshwar Gidc, Gujarat

- GST NO. : 24ACNPC1767D1ZW

Mobile : View Mobile Number

Cooling Process Equipment

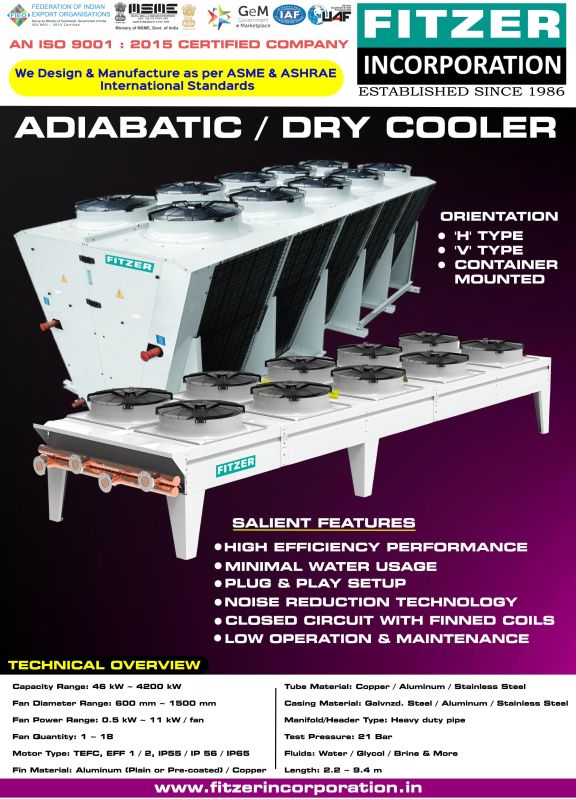

Leading Manufacturers, Exporters and Wholesaler of Adiabatic Cooler, Dry Cooling Towers, Air Cooled Chiller, Water Cooled Chiller, Evaporative Condenser and Closed Loop Cooling Tower from Ankleshwar.

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Stainless Steel |

| Air Throw Coverage | 35 Ft |

| Cooling Media | Honeycomb |

| Voltage | 380V |

| Weight | As Per Designed |

| Warranty | 1 Year |

| V Type | Coolers for reduced plan area |

| Flat-bed | Coolers with horizontal or vertical airflow |

| Box Type | Fully packaged units incorporating pump, tank and starting equipment. |

| International Standard | ASME. TEMA, ASHRAE, IBR, ASME-U-STAMP & R -STAMP |

Air Blast and Adiabatic Coolers for sealed water cooling systems and reducing maintenance costs on both the cooler and the equipment it serves with the added benefit of reducing health and safety issues created by the operation of evaporative cooling towers. Units are available from 5 Kw upwards.

Features :

- - Chemical water treatment not required.

- - Cleaning and chlorination not required.

- - Sealed system, no contamination of the water algie does not grow.

- - Water losses through evaporation is eliminated.

- - Low operating noise levels.

- - Low operating costs.

- - Minimal plan area

- - Unsightly plumes of water vapor coming from your cooling equipment is stopped.

Construction Options :

- Tubes : Copper, M.S or stainless steel

- Fins : Aluminium, copper, G.I or stainless steel

- Fans : Axial type at variable speeds to unit customer requirements

- Casework : Galvanized steel, external painting, aluminium or stainless steel

| Business Type | Manufacturer, Exporter |

| Feature | cools efficiently using Air-Cooled HX without water evaporation, cost-saving, water-scarce regions. |

| Brand Name | FITZER |

| Material | FRP, Stainless Steel,Copper tubes (5/8" OD) with galvanized steel frame |

| Driven Type | Electric |

| Color | Grey, Light White, INDUSTRIAL GRADE,As per industrial Grade |

| Condition | New |

| Automatic Grade | Automatic, Fully Automatic, Semi Automatic |

| Power | upto 5000 KW |

| Cooling Type | Closed-circuit air cooling system |

| Voltage | 220V |

| Capacity | As per Capacity in KW |

| Type | Dry Cooling Towers, Heav Duty,Dry Cooling Tower - V & H Shape |

| Weight | As Per Designed |

| Warranty | 1year, 1year,One Year |

| After-Sales Service Provided | Yes |

| Country of Origin | India |

| Temperature | 50-100℃ |

| Gauge Thickness | 10-15mm |

| International Standard | ASME. TEMA, ASHRAE, IBR, ASME-U-STAMP & R -STAMP |

| Cooling Method | Air-cooled heat exchangers with extended fins - Water Consumption: Zero (closed-loop system) - Material: Copper tubes (5/8" OD) with galvanized steel frame - Fan Type: Axial flow fan |

| Water Consumption | Zero (closed-loop system) |

| Fan Type | Axial flow fan, aerodynamically balanced - Motor: IP55-rated, low-speed for efficiency and noise reduction - Applications: Power plants, industrial cooling, HVAC systems - Construction: No |

| Motor | IP55-rated, low-speed for efficiency and noise reduction - Applications: Power plants, industrial cooling, HVAC systems - Construction: Non-corrosive fiber glass/GI panels, heavy-duty base fr |

| Application | Power plants, industrial cooling, HVAC systems,Dry Cooling |

| Size | As per Capacity |

| Product Code | FI-DCT- |

| Port | Mumbai & Gujarat |

| Payment Terms | T/T, Other |

| Delivery Time | 3-4 Weeks |

| Packaging Details | Wooden Pallet Packaging |

A Dry Cooling Tower is a type of cooling system that operates without water evaporation, making it ideal for regions with water scarcity. It functions by transferring excess heat from industrial processes through a closed-loop system, where heat is dissipated via air-cooled heat exchangers with extended fins.

Key Features:

- Closed-Circuit Operation: Heat is transferred through a surface separating ambient air from the working fluid (typically water or a water-glycol mixture).

- Air Cooling Technology: Uses natural or mechanical draft to move air over heat exchangers, eliminating the need for water evaporation.

- Minimal Water Consumption: Unlike wet cooling towers, dry cooling towers do not require makeup water, reducing operational costs.

- Applications: Commonly used in power plants, industrial cooling, solar energy systems, and HVAC applications.

Technical features

- Casing in galvanized steel, painted with epoxy (RAL 9002)

- Battery frame in galvanized steel

- Copper tubes and aluminium fins

- Two heat exchanger lengths available:

- DUAL versions available, with two independent cooling circuits and fan sections

- 3 possible configurations depending

- Electrical box for fans connections and associated protection (option)

- Aluminium-coated fins (option)

- Copper fins (option)

- Stainless steel tubes (option)

| Business Type | Manufacturer, Exporter, Supplier |

| Catalog | |

| Type | Air Cooled |

| Chiller Shape | Rectangular |

| Warranty | 1 Year |

| Driven Type | Electric |

| Material | Stainless Steel |

| Certification | International Standard |

| Phase | Single Phase |

| Weight | As per designed |

| Usage | Dairy, Pharmaceutical, Chemical |

| MOQ | 1 |

| Product Name | Blast Freezer |

| MOC | SS |

Our air-cooled scroll chillers can reduce your total cost of ownership because they are engineering for lower life cycle costs and reliability through design simplicity. Our compressor technology is direct drive, low speed (3600 rpm) with only two rotating parts for high reliability and efficiency. Optimized compressor parts profiles are designed specifically for chilled water applications to optimize full and part-load efficiency. Our 'Smart H' Microprocessor provides greater reliability through a proactive control strategy, safety functions with simple diagnostics and easy interface with any building automation / energy management using a single twisted pair of wires. Hiver air-cooled scroll chillers are the right choice for tight temperature control in virtually any application.

Our compact chillers install easily and quickly into most building / factory layouts, making them ideal choices for retrofit or new building designs.

- Single Compressor Series : HACS

- Dual Compressor Series : HACD

- Multiple Compressor Series : HACM

- Comfort Air-Conditioning

- Chemical & Pharmaceuticals

- Engineering & Industrial

- Commercial & Institutional

- Hospitals & Hospitality

- Telecommunications

- Laser Technology

- Welding Engineering

- Aeronautical Testing Facility

- Defense Laboratory Testing facility

- Computer Chip Manufacturing

- Medical Process

- Blow Mold Machines

- Injection Molding Machines

- Plastics Processing

- Electroplating Industry

- Factory Furnaces

- Laboratory Equipments

- Food and Beverage Industry

- Food Process Industry

- Anodizing Plants

- Dye and Pigment Manufacturing

- Plasma Spray Machines

- Induction Hardening Machine

- Foundries

- Superior Relaibilty

- High Energy Efficiency

- Long Equipment Life

- Adaptive frequency drive option available

- Clean Energy & Intelligent Mangements

- Solution for Energy Saving Equipments

- Easy Interface with BMS through protocols

- Ozone friendly refrigerant HFC134a, HFC407c

- Highly reliable desgin with best class cop

- Equipped with advanced 'H-smart' microprocessor based controller

- Efficient lubrication, even in the event of power failure

- Body is made up of Galvanized Steel

- Powder Coated / Polyurethane paint.

- Anti-freeze safety and water flow switches.

- World-class safety controllers for equipments & compressors

- Custom built machine enquiries are also entertained

- 100% functionally tested

- Equipment extended warrnty options are available up to 10 yrs.

- Site support with Amc options are available for entire life of equipments.

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Water Cooled |

| Material | Stainless Steel |

| Application | Industrial |

| Weight | As Per Designed |

| Voltage | 220V |

| Driven Type | Electric |

| Warranty | 1 Year |

| International Standard | ASME. TEMA, ASHRAE, IBR, ASME-U-STAMP & R -STAMP |

| Business Type | Manufacturer, Exporter |

| Catalog | |

| Type | Evaporative |

| Material | Stainless Steel |

| Application | Industrial Use |

| Weight | As Per Designed |

| Voltage | 380V |

| Warranty | 1 Year |

| International Standard | ASME. TEMA, ASHRAE, IBR, ASME-U-STAMP & R -STAMP |

An evaporative condenser is a condenser integrated into a cooling tower which rejects the latent heat of condensation of refrigerant (Ammonia/Freon) through a coil to the surroundings by means of evaporation.

Water sprayed onto the coil exchanges heat with the refrigerant. A small quantity of water is evaporated into the air thereby cooling the remaining water cascading to the basin at the bottom. Post evaporation the saturated air passes through the drift eliminators and then forced out using a fan.

Construction And Working Of Evaporative Condenser :

In evaporative condensers, both air and water are used to extract heat from the condensing refrigerant. Figure shows the schematic of an evaporative condenser. Evaporative condensers combine the features of a cooling tower and water-cooled condenser in a single unit. In these condensers, the water is sprayed from top part on a bank of tubes carrying the refrigerant and air is induced upwards. There is a thin water film around the condenser tubes from which evaporative cooling takes place. The heat transfer coefficient for evaporative cooling is very large. Hence, the refrigeration system can be operated at low condensing temperatures (about 11 to 13 K above the wet bulb temperature of air). The water spray counter current to the airflow acts as cooling tower. The role of air is primarily to increase the rate of evaporation of water. The required air flow rates are in the range of 350 to 500 m3/h per TR of refrigeration capacity.

| Business Type | Manufacturer, Exporter, Supplier |

| Catalog | |

| Type | Closed Loop |

| Application | Industrial |

| Weight | As Per Designed |

| Color | Grey |

| Voltage | 380V |

| Capacity | 500-1000L |

| Warranty | 1 Year |

| International Standard | ASME. TEMA, ASHRAE, IBR, ASME-U-STAMP & R -STAMP |

e manufactures two types of closed circuit cooling tower and combined flow and counterflow coolingtower. Closed Circuit Cooling Tower are suitable for Thermal Power Plants. Closed Circuit cooling tower certain processes needs a closed loop, that's why the process water for cooling does not come in make contact with the full of atmosphere air. Closed loop type cooling is minimizes process fouling.

Types of Closed Circuit Cooling Tower

- Combined Flow

- Counter Flow

We may well include various percent of the cooling water from the available water resources to the closed circuit cooling system and we be able to decrease the cooling tower size.

Mixing ration means the percentage of the added water. If our mixing ratio is zero, it is called absolutely closed system. When the mixing ratio is 100%, it is called an open system.

Closed Circuit Cooling Tower Water Temperature

Closed Circuit Cooling Towers are accomplished of incoming fluid temperatures as high as 180ºF (82.2ºC),.

Closed Circuit Cooling Tower Design

Our Closed Circuit Cooling System gives completely rated thermal presentation, which also by yourself verified over special types of flow and high temperature requirements. Closed Circuit Cooling Towers are high effciency and water saving.