Ankleshwar Gidc, Gujarat

- GST NO. : 24ACNPC1767D1ZW

Mobile : View Mobile Number

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | FITZER |

| Material | Stainless Steel, (SS304 / SS316 / SS316L), Inconel, Monel, Nickel Alloy, Graphite, PTFE-lined Composite |

| Finishing | Non Polished, Polished, Electro-polished, coated, or custom surface treatment (based on customer need),Non-Polished Polished BA/2B finish (optional) |

| Click to view more | |

Product Details

Carton (bulk supply)

Shock-proof packing available for export

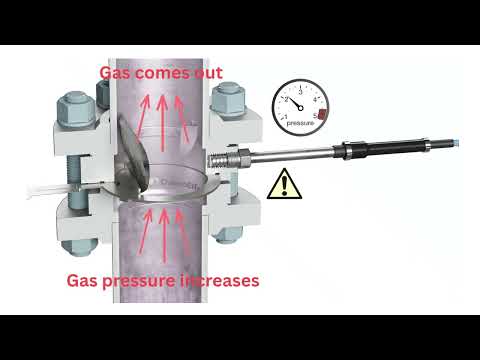

A rupture disc (also called bursting disc) is a highly reliable pressure safety device engineered to protect industrial equipment, processes, and personnel from dangerous overpressure or vacuum conditions. When the system pressure reaches the disc’s predefined burst limit, the disc ruptures instantly, allowing excess pressure to escape and preventing catastrophic equipment failure.

What is a Rupture Disc?A rupture disc is a non-reclosing pressure relief device installed in pipelines, vessels, reactors, heat exchangers, storage tanks, and other pressurized systems. It is precision-designed to burst at a specific pressure rating, ensuring immediate, fail-safe protection.

Key Functions-

Safely relieves excess pressure

-

Prevents explosions and system damage

-

Protects personnel and equipment

-

Enables safe operation of high-pressure processes

Rupture discs are manufactured using high-grade materials based on process requirements:

-

Stainless steel

-

Nickel, Inconel, Monel

-

Aluminum

-

Graphite

-

PTFE / Plastic materials

These materials offer excellent performance in high-temperature, corrosive, abrasive, or hazardous industrial environments.

ApplicationsRupture discs are widely used in:

-

Chemical & Petrochemical Plants

-

Pharmaceuticals & API Processing

-

Oil & Gas Industry

-

Food & Beverage Processing

-

Power Plants & Boilers

-

Tanks, Pressure Vessels & Reactors

-

Pipelines & Storage Systems

-

Cryogenic and Vacuum Systems

-

No moving parts → Zero mechanical failure

-

Maintenance-free since there is no wear mechanism

-

Instant response to sudden pressure spikes

-

Cost-effective compared to safety relief valves

-

Can be used with relief valves for dual protection

-

High accuracy in burst pressure rating

-

Suitable for extreme environments (temperature, corrosion, explosive atmosphere)

Rupture discs are often installed upstream of a safety relief valve to:

-

Protect the valve from corrosion or contamination

-

Improve sealing performance

-

Reduce leakage

-

Enhance system safety and redundancy

Uses of Rupture Discs

Rupture discs are widely applied wherever reliable pressure relief is essential to safeguard equipment, processes, and personnel from dangerous overpressure or vacuum conditions. Key applications include:

-

Pressure Vessels: Installed in boilers, reactors, and other pressure vessels to prevent excessive pressure buildup and reduce the risk of explosions.

-

Pipelines: Used in pipelines to protect the system from overpressure caused by blockages, pump malfunctions, or sudden pressure spikes.

-

Chemical & Petrochemical Processes: Provide safety against pressure surges resulting from chemical reactions, thermal expansion, or equipment failure.

-

Aerospace & Aviation: Applied in aircraft fuel tanks, hydraulic systems, and other components to manage overpressure and vacuum conditions.

-

Pharmaceutical & Biotech Industries: Protect sensitive processing equipment from overpressure due to reactions or unexpected operational issues.

-

Food & Beverage Processing: Ensure safety in storage tanks and production equipment by providing effective pressure relief during processing operations.

Looking for "Rupture Discs" ?

Explore More Products

Our Blogs