Ankleshwar Gidc, Gujarat

- GST NO. : 24ACNPC1767D1ZW

Mobile : View Mobile Number

Refrigeration Process Equipment

Leading Manufacturers, Exporters and Wholesaler of ICE BUILDING TANK (IBT), Industrial Air Washers, Industrial CO2 Based Ultra Low Temp Chillers, Panel Air Conditioners, IQF Tunnel Freezer and Cold Storage Room from Ankleshwar.

| Business Type | Manufacturer, Exporter |

| Country of Origin | India |

| Type | Ice Bank Tank |

| Material | Stainless Steel, M.S. Fabricated IBT |

| Application | Milk Cooling, Cooling Energy Storage |

| Weight | 0-1000 Kg |

| Color | White |

| Feature | Cost Effective, Durable, Eco Friendly Refrigerant, Energy Efficiency |

| Condition | New |

| Design Type | Customized, Standard |

| Automation Grade | Automatic |

| Desired Temp | As Per Requirement |

| Tank Insulation | Better Insulation |

| Name | ICE BANKING TANKS (IBT) |

| Usage | DAIRY INDUSTRY |

| Product | quick process in short time with certain limit of power load. |

| No need of civil & fabrication work at customer site | Yes |

| Easy to lift & shift | Yes |

| Energy efficient | Yes |

| Requires less connected power load | Yes |

| The ice water intensively cools the product without any risk | Yes |

| Power supply is not required once ice formation is completed | Yes |

| No requirement of Cooling Tower and water supply (For Air-Cooled type) | Yes |

| Wide capacity with storage tank upto 1,00,000 Ltr./33,000 KG ice formation per day | Yes |

| Cooling energy storage capacity upto 900 TR/Day | Yes |

| Product Code | FI-IBT- |

| Port | Mumbai & Gujarat |

| Payment Terms | T/T, Other |

| Delivery Time | 3-4 Weeks |

| Packaging Details | Wooden Packaging |

IBT is a system, which stores energy in the form of ICE.

It is applicable in Dairy Industry for quick process in short time with certain limit of power load.

FREON AS A REFRIGERANT:

Features:

- No need of civil & fabrication work at customer site

- Easy to lift & shift

- Energy efficient

- Better insulation

Advantages:

- Requires less connected power load

- The ice water intensively cools the product without any risk

- Power supply is not required once ice formation is completed

- No requirement of Cooling Tower and water supply (For Air-Cooled type)

- Wide capacity with storage tank upto 1,00,000 Ltr./33,000 KG ice formation per day

- Cooling energy storage capacity upto 900 TR/Day

AMMONIA AS A REFRIGERANT:

Features: Option-1

- Portable IBT

- No need of civil & fabrication work at customer site

- Easy to lift & shift

- Energy efficient

- Better insulation

Features: Option-2

- M.S. fabricated IBT at customer site with civil construction

- Customised IBT

- Energy efficient

- Better insulation

Advantages:

- Requires less connected power load

- The ice water intensively cools the product without any risk

- Power supply is not required once ice formation is completed

- Wide range of storage tank

- Cooling energy storage

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Polyurethane Foam Panel,Polyurethane Foam Panel |

| Driven Type | Electric |

| Color | WHITE,WHITE |

| Condition | New |

| Automatic Grade | Automatic, Fully Automatic, Manual, Semi Automatic |

| Application | Industrial Use,Air washers reduces temperature upto 19 Deg C in Hot & Dry Climates. |

| Certification | ISI Certified, ISO 9001:2008 Certified |

| Feature | Accuracy Durable, Corrosion Resistance, High Quality, High Tensile |

| Voltage | 415 V |

| Type | Industrial Air Washers,INDUSTRIAL AIR WASHER UNIT |

| Thickness | 100 MM |

| Weight | AS PER CAPACITY |

| Warranty | ONE YEAR |

| Country of Origin | India,India |

| Energy Efficient | Consumes upto 80% less electricity than refrigerated air conditioning. |

| Economical | Air washer Technology is Economic, natural & sustainable. |

| Air Quality | Air washer Improves indoor air quality by removing fumes & odors . |

| Cooling Efficiency | Evaporative cooling efficiency increases as temperature rises. |

| Fresh Air | Delivers 100% fresh, filtered, healthy Natural air. |

| Pump | Submersible type water pump for continuous water supply. |

| Area | No need to close doors & windows. |

| Productivity | Improves productivity in industries through fresh, clean & cool air. |

| Capex & Opex | Low Capex & Opex. |

| Brand | FITZER |

| Size | AS PER CAPACITY REQUIREMENT |

| Product Code | FI-AWU= |

| Port | Mumbai & Gujarat |

| Payment Terms | Other |

| Delivery Time | 3-4 Weeks |

| Packaging Details | WOODEN PALLET |

Air washers are industrial cooling equipment used to maintain desired space temperature and humidity condition for comfort or process requirements.

Working of Air Washer:

In Air Washers air comes in direct contact with water which is sprayed over cellulose pads .As the hot air come in contact with water ,water evaporates and carries away heat of air in the process. The outlet condition of air depends upon the difference between Dry bulb and wet bulb temperature of ambient air.

Air washer with improved efficiency:

FITZER - The manufacturer of air washer also provides innovated compact Air Washers with 3 or 4 side pads for more area coverage and better cooling efficiency.

Features

Single speed wired Remote controller with single phasing and overload protection.

Multi speed option with VFD to control air flow as per requirement.

Low running cost compared to Air Conditioners.

Rust free Stainless Steel Tanks.

AMCA Certified Centrifugal Blowers.

IE2 Efficiency, IP 55 Protected Electric Motors of Siemens /ABB/CG/Havells make.

Very Effective cooling in hot & dry climate areas.

Unique and non-clogging type water distribution system.

Auto water drain facility.

You will also get a gamut of added benefits of using them in any industrial area where proper cooling and ventilation is required to ensure comfortable working environment.

BENEFITS OF AIR WASHERS

Air washers reduces temperature upto 19 Deg C in Hot & Dry Climates.

Consumes upto 80% less electricity than refrigerated air conditioning.

Air washer Technology is Economic, natural & sustainable.

Air washer Improves indoor air quality by removing fumes & odours.

Evaporative cooling efficiency increases as temperature rises.

Delivers 100% fresh, filtered, healthy Natural air.

Submersible type water pump for continuous water supply.

No need to close doors & windows.

Improves productivity in industries through fresh, clean & cool air.

Low Capex & Opex.

Advantages of Air washers

Air washers has the advantage of being an hybrid appliance, a combination of an air purifier and a humidifier. Like conventional humidifiers, air washer adds therapeutic moisture to the air.

And, like a conventional air purifier, an air washer removes symptom-triggering allergens from the air. Therefore, they not only cool the air but have the capability of soothing your uncomfortable dry air symptoms and easing your allergies.

Fan Features

The fans are of international standard and are AMCA certified.

Centrifugal blower forward / backward curved as per static pressure requirements.

The fans are static and dynamically balanced.

Electric Motors

TEFC Squirrel Cage Induction Motor, IP 55 Protected VFD Compatible induction motor of Standard make

Siemens/CG/Havells /ABB etc.

Cooling Pads

High quality Evaporative Cooling Pads CELdek-Munters/ Hu-Tek / Eco-Cool make are used in Air washer for high saturation and

cooling efficiency upto 90%. The Cooling Pad of Air Washers is made of cellulose ( Pulp ) sheet and available in 5 & 7mm flute sizes. The Cellulose Pad is cross-corrugated and coated with anti-rot, rigidifying and wetting agent.

| Business Type | Manufacturer, Exporter |

| Brand Name | FITZER |

| Color | Light Grey With Blue Accents OR Green |

| Power | 30 KW |

| Voltage | 400–415V, 3 Phase, 50 Hz |

| Weight | Approx. 2000–2500 Kg (Model Dependent) |

| Temperature Range | +10 Deg. C To -50 Deg. C |

| Warranty | 1 Year |

| Country of Origin | India |

| Refrigerant | CO₂ (R-744) / Optional R-1270 (Propylene) |

| Operating Temperature Range | –60°C to +15°C |

| Process Fluid | Syltherm XLT or equivalent synthetic fluid |

| Cooling Media for Condenser | 30% Propylene Glycol + Water |

| Evaporator Type | Shell & Tube / Brazed Plate (SS Construction, PED Certified) |

| Condenser Type | Shell & Tube, SS Construction, PED Certified |

| Motor | ABB ATEX Certified, 30 kW, 415V, 3Ph, 50Hz |

| Pump Type | KSB / Flowserve, Back-Pull Out Type, SS Impeller, Non-Sparking Coupling |

| Pump Configuration | 2 Nos. (1 Running + 1 Standby) |

| Panel Type | Purged Type with Vortex Cooling (ATEX/IECEX Certified) |

| PLC / HMI | Siemens PLC with 7” Color Touchscreen |

| Electrical Items | Schneider make, rated for +55°C operation |

| Insulation | Nitrile Rubber with Armaflex Protective Layer |

| Installation | Indoor, Skid Mounted, Factory-Assembled |

| Operating Voltage | 400–415V ±10%, 3 Phase, 50 Hz ±5% |

| Noise Level | ≤ 95 dBA @ 1 meter |

| Material of Construction | All Wetted Parts in Stainless Steel (SS 304 / SS 316) |

| Product Type | Water-Cooled CO₂ Based Process Chiller,Water-Cooled, CO₂ Based Ultra Low Temp Chiller |

| Material | Stainless Steel (SS 304 / SS 316) |

| Certification | CE Certified / PED Certified / ATEX Zone-2, IIA, T3 / ISO 9001:2015 |

| Finishing | Polished, Powder Coated |

| Width | Custom-Built as per Capacity (Approx. 1200–1500 mm) |

| Driven Type | Electric |

| Tank Capacity | Integrated Circulation System (10.65 m³/hr Flow) |

| Phase | Three Phase |

| Mounting Type | Skid Mounted (Indoor Installation) |

| Noise | ≤ 95 dBA @ 1m |

| Overall Length | Approx. 2500–3000 mm (Model Dependent) |

| Tonnage | Equivalent to ~6.2 TR Cooling Capacity |

| Corrosion Resistance | Yes |

| Compressor Type | Open Type Screw Compressor (GEA Grasso, Germany),Open Type Screw Compressor (GEA – Germany) or Equivalent. |

| Machine Structure | Horizontal Skid Frame with Vertical Components |

| Mobility | Fixed (Stationary Industrial Installation) |

| Operating Type | Automatic (PLC Controlled) |

| Application | Air Cooling, Process Cooling / CO₂ Liquefaction / Industrial Cooling |

| Features | Rust Proof, Long Life, High Performance, Easy To Operate, Rust Proof, Long Life, High Performance, Easy to Operate, Energy Efficient |

| Energy Consumption | Optimized High Efficiency System (Low kW/TR) |

| Dimension (LxWxH) | Approx. 2800 × 1400 × 1700 mm (Typical for 22 kW Model) |

| Inverter Technology | Yes – VFD Controlled Secondary Pump |

| Cooling Capacity | 18 TO 410 kW (with Safety Margin),18 to 410 kW |

| Star Rating | 5 Star Equivalent (Industrial Grade Efficiency) |

| Chiller Shape | Rectangular Skid-Mounted Package |

| Cooling Air Flow | Not Applicable (Water-Cooled System) |

| Evaporator | Shell & Tube Type / BPHE – Full SS Construction |

| No. Of Compressor | 1 No. (Open Type Screw) |

| Frequency Hz | 50 Hz |

| Water Flowing Rate | 13.65 m³/hr (Cooling Water) or As per requirement. |

| Product Code | FI-ULTC-900 |

| Port | Mumbai & Gujarat |

| Payment Terms | T/T, Other |

| Delivery Time | 6-8 Weeks |

| Packaging Details | Wooden Pallet & Box |

CO₂ Based Chillers are advanced, eco-friendly cooling systems designed to deliver high performance, energy efficiency, and sustainability. Each unit is custom-engineered for specific process cooling applications and is continuously tested for a wide range of industrial and commercial uses.

These chillers operate efficiently across medium, low, and ultra-low temperature ranges, making them ideal for demanding environments that require precise temperature control and long-term reliability.

Applications:

-

Supermarket & Retail Refrigeration

-

Industrial Gas Cooling

-

Cold Storages & Freezing Plants

-

Process Cooling in Food, Pharma & Chemical Industries

-

General Industrial Cooling Requirements

Key Features:

✅ Eco-Friendly Refrigerant: Utilizes natural CO₂ (R-744) — non-toxic, non-flammable, and ozone-safe

✅ Energy Efficient Design: Optimized components ensure high COP and reduced power consumption

✅ Hazardous Area Certified: ATEX, Zone-2, IIA, T3 approved for safety-critical environments

✅ High-Grade Materials: All wetted parts in stainless steel, PED certified for durability

✅ Global Quality Components: GEA screw compressor, ABB ATEX motor, Siemens PLC

✅ Plug-and-Play Unit: Factory-assembled, skid-mounted, and tested

✅ Remote Control: PLC + HMI touchscreen interface for seamless operation

✅ Low Maintenance: Simple design, corrosion-resistant construction, and long service life

✅ Make in India: Designed and manufactured in India with world-class standards

Technical Highlights:

-

Refrigerant: CO₂ (R-744)

-

Cooling Capacity: Custom-built as per client requirement

-

Temperature Range: Medium to ultra-low (as per application)

-

Applications: Industrial & Commercial Cooling

Standard Accessories:

-

PED Certified Suction Accumulator & Liquid Receiver

-

SS Oil Separator with Demister

-

Danfoss Electronic Expansion Valve

-

Honeywell Pressure/Temperature Transmitters

-

SS Instrument Tubing & Swagelok Fittings

-

Siemens PLC & 7” HMI for Control & Monitoring

🌍 Future Sustainability & Carbon Emission Impact

FITZER's CO₂ Based Chiller Technology represents a major step forward in sustainable industrial refrigeration. By using carbon dioxide (R-744) — a natural refrigerant with zero ozone depletion potential (ODP) and an ultra-low global warming potential (GWP ≈ 1) — these chillers directly contribute to reducing carbon emissions and meeting future global climate goals.

As the world moves away from synthetic refrigerants like R-22, R-134a, and R-404A, which have high GWP values, CO₂-based systems offer a clean, future-ready alternative that aligns with upcoming F-Gas and HFC phase-out regulations.

In addition, CO₂ chillers operate with higher energy efficiency in low-temperature applications, leading to lower electricity usage and reduced indirect emissions. Over a system’s life cycle, this translates into:

-

Up to 40% lower total greenhouse gas impact

-

Reduced operational carbon footprint

-

Compliance with ESG, LEED, and green certification standards

By adopting this technology today, industries future-proof their operations against environmental regulations while enhancing brand image as a sustainable manufacturer.

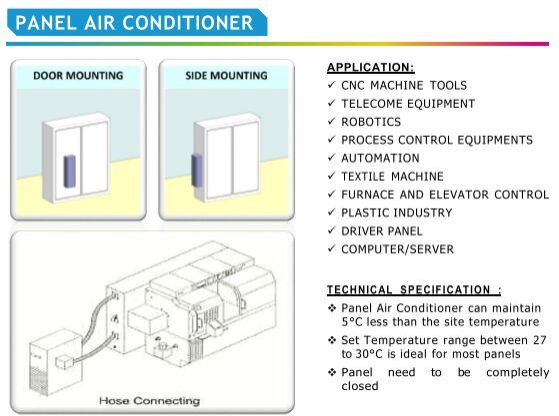

| Business Type | Manufacturer, Exporter |

| Series Name | Panel Air Conditioner |

| Night Glow Function On Remote Buttons | NA |

| Remote Type | Yes |

| Overall Weight | (Actual Weight Depends On Selected Model.) |

| Auto Restart | Yes |

| Star Rating | 5 Star |

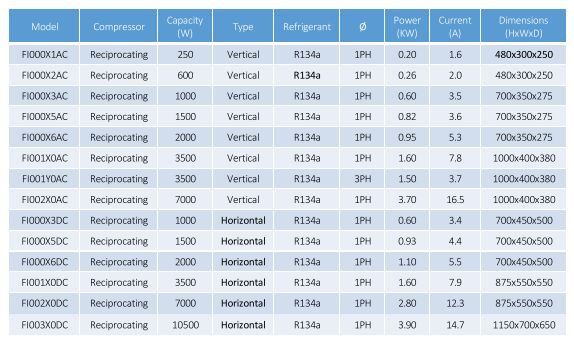

| Refrigerant | R134a |

| Country of Origin | Made In India |

| Compressor | Reciprocating Compressor |

| Airflow | Two-circuit Internal & External Cooling Airflow |

| Warranty | One Year |

| Phase | Single |

| Frequency | 50Hz,60Hz |

| Type | Floor Standing,Cabinet Mounting |

| Features | Turbo Cool,Energy Saver,100% Copper,High Energy Efficiency Rotary Compressor,Energy Efficient Design,Balanced System Architecture,High-Efficiency Heat Exchanger & Airflow |

| Cooling Capacity (Watt) | 2640 Watt,3450 Watt,4750 Watt,5100 Watt,5110 Watt,6330 Watt,6350 Watt,250 W 600 W 1000 W 1500 W 2000 W 3500 W 7000 W 10500 W |

| Refrigerant Type | R134a Refrigerant |

| Nominal Cooling Capacity (Tonnage) | 0.07 Ton 0.17 Ton 0.28 Ton 0.42 Ton 0.57 Ton 1 Ton 2 Ton 3 Ton |

| Condenser Type | Copper,Standard Copper/aluminum Finned Coil. |

| Cooling Capacity | 250 W 600 W 1000 W 1500 W 2000 W 3500 W 7000 W 10500 W |

| Compressor Type | Reciprocating Compressor (All Models Listed) |

| Width | (Actual Size Depends On Selected Model.) |

| Voltage | 220V,230V,240V,380V,440V |

| Model Number | FI000X1AC |

| Size | (Actual Dimensions Depends On Selected Model.) |

| Usage/Application | FITZER Panel AC Units Are Designed For Cooling Electrical And Electronic Enclosures |

| Power Consumption | 0.20 KW TO 4 KW |

| Input Power | 220V 230V 240V 380V 440V (Actual Voltage Depends On Selected Model.) |

| Power Supply | Depending On The Model: 1 Phase (1PH) 3 Phase (3PH) 220V 230V 240V 380V 440V |

| Body Material | GI Sheet Metal (Powder Coated) / SS (on Request) |

| Brand Name | FITZER |

FITZER panel air conditioner units are a perfect solution for cooling electrical and electronic control panels.

Engineered with a deep understanding of high sensible cooling requirements, these units are built for continuous, long-hour operation. Their robust components and high-reliability electronics, combined with a high-ambient design, ensure uninterrupted performance of your machines throughout the year.

The range is available in multiple capacities from 250 to 10000 W/h on a single chassis, with flexible mounting, power supply, and refrigerant options to meet diverse application needs.

Product Features

-

Energy Efficient Design

Optimized for reduced power consumption and long-term performance. -

Balanced System Architecture

Ensures stable, reliable cooling across all operating conditions. -

High Ambient Temperature Compatibility

Designed to perform efficiently even in elevated ambient temperatures. -

High-Efficiency Heat Exchanger & Airflow System

Delivers superior heat transfer and optimal air circulation. -

Durable GI Sheet Metal Construction (Powder-Coated)

Provides strong corrosion resistance and long service life. -

Maximum Utilization of Natural Heat Transfer Principles

Engineered for scientifically optimized thermal performance. -

Easy-Mount Studs for Quick Installation

Simplifies setup, saving time and effort. -

CE Certified – European Conformity

Meets international safety and quality standards.

Available on request in a stainless steel 304 body, with top-mount and customized power supply options.

Due to continuous product enhancements and ongoing innovation, FITZER reserves the right to modify the design, technical specifications, and dimensions without prior notice.

| Business Type | Manufacturer, Exporter |

| Catalog | |

| Number Of Flower | IQF |

| Storage Condition | Air Cooled |

| Availability | As Per Designed |

| Country of Origin | 440V |

| Power | 3-6kw |

| Driven Type | Electric |

| Total Carbohydrate | 1 Year |

| Capacity | 200 kg Per hour to 2500 kg per hour |

| International Standard | ASME. TEMA, ASHRAE, IBR, ASME-U-STAMP & R -STAMP |

IQF Quick Freezing System individually freezes various types of food including fruit, meat, seafood and bakery rapidly at –60℃.

Quick freezing at very low temperatures in a short amount of time prevents ice crystals from forming, a key technology in efficiently maintaining food characteristics, freshness and quality in highest conditions.

Domestic quick freezing generally happens at around –30℃~-40℃. For instance, fish must be quick frozen at below –50℃ to maintain cell integrity and moisture.

Longer freezing times result in destruction and deformation of cells and nutritions, significantly reducing flavor and quality.

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Insulated |

| Application | Industrial |

| Color | Grey |

| Voltage | 440V |

| Power | 10-20kw |

| Driven Type | Electric |

| Warranty | 1 Year |

| Weight | As per designed |

| International Standard | ASME. TEMA, ASHRAE, IBR, ASME-U-STAMP & R -STAMP |

Cold rooms and storages are preservation chambers, usually assembled at the deployment site to desired dimensions and cooling specifications of the end user.

These chambers are generally built using insulating materials polyurethane foam (PUF), highly efficient & precisely designed to cater a wide temperature range from +15 ˚C to -40 ˚C, high quality doors & accessories and refrigeration units such as evaporating and condensing units specially designed for energy efficient, low noise, easy maintenance and compact size which gives the same performance for many years.

Our cold rooms are largely used in the industries like hospitality, dairy, ice cream, horticulture, medicare, pharmaceuticals, frozen products and speciality applications.

Our cold room have several benefits such as,

- Easy to assemble and dismantle

- All Side PVC gasket

- Homogeneous PUF density

- High ambient refrigeration design

- Wall to top cam-lock joints

- Fully Customized