Ankleshwar Gidc, Gujarat

- GST NO. : 24ACNPC1767D1ZW

Mobile : View Mobile Number

Heat Exchangers

Leading Manufacturers, Exporters and Wholesaler of Air Cooled Heat Exchanger, Box Type Heat Exchanger, Fully Welded Plate Heat Exchanger, Graphite Plate and Frame Heat Exchanger, Kettle Reboiler Heat Exchanger, Paddy Dryer Heat Exchanger, Pillow Type Plate Heat Exchanger, Rice Mill Heat Exchanger, Shell & Tube Heat Exchanger, Spiral Heat Exchanger, Tube In Tube Heat Exchanger, U Tube Heat Exchanger, After Cooler, Inter Cooler, charge air coolers, Marine Engine Oil Cooler, Convection Recuperator and pressure vessels from Ankleshwar.

| Business Type | Manufacturer, Exporter |

| Catalog | |

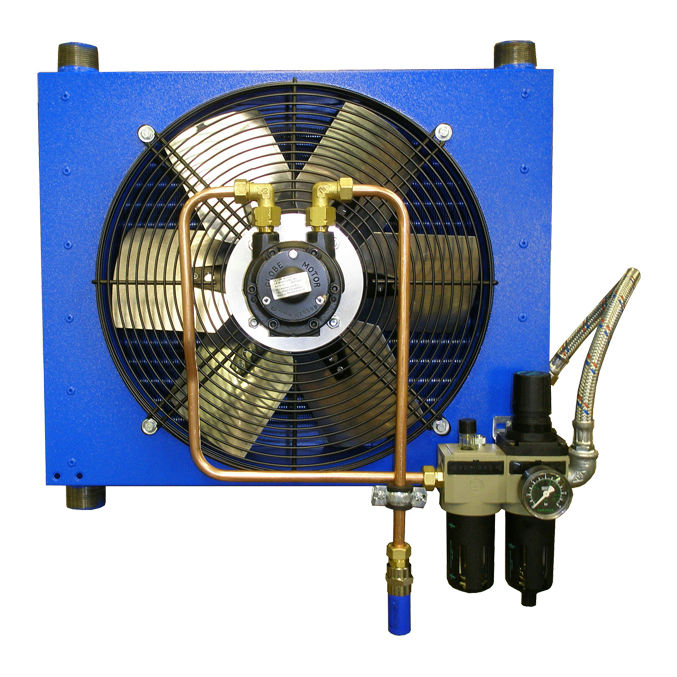

| Number Of Flower | Air Cooled |

| Material | Stainless Steel |

| Country of Origin | 380V |

| Total Carbohydrate | 1 Year |

| Shape | Rectangular |

| Finishing | Polished |

| Availability | As Per Designed |

| Capacities offered: 1 TPD to 100 TPD of ice | High durability, minimum maintenance |

| Complete spare parts provided | Design/Engineering simplicity |

| High energy efficiency | Available in two refrigerant variant Ammonia and Freon |

| Easy Operations No requirement of skilled workers | Prompt service |

| International Standard | ASME. TEMA, ASHRAE, IBR, ASME-U-STAMP & R -STAMP |

Introduction to air-cooled heat exchangers

Water shortage and increasing costs, together with more recent concerns about water pollution and cooling tower plumes, have greatly reduced industry's use of water cooled heat exchangers. Consequently, when further heat integration within the plant is not possible, it is now usual to reject heat directly to the atmosphere, and a large proportion of the process cooling in refineries and chemical plants takes place in Air Cooled Heat Exchangers (AC-HEs).

There is also increasing use of Air Cooled Condensers for power stations. The basic principles are the same but these are specialized items and are normally configured as an A-frame or "roof type". These condensers may be very large-the condensers for a 4000 MW power station in South Africa have over 2300 tube bundles, 288 fans each 9.1 m in diameter and a total plot area 500 m X 70 m.

AC-HEs for process plants are normally just called Aircoolers, but should not be confused with devices for cooling air (best described as Air Chillers).

The design of an AC-HE is more complex than for a Shell and Tube Heat Exchanger, as there are many more components and variables.

The structure of an AC-HE is painted or galvanized, depending on customer specification. However, the costs are roughly the same if a multiple coat paint system is specified. Often the painted units are more expensive. There seems to be a trend toward more galvanized structures because they require virtually no maintenance. Painted structures require touch-up after installation and they often rust anyway.

Air-cooled heat exchangers are used extensively throughout the oil and gas industry, from upstream production to refineries and petrochemical plants, under high pressure and high temperature conditions, as well as corrosive fluids and environments.

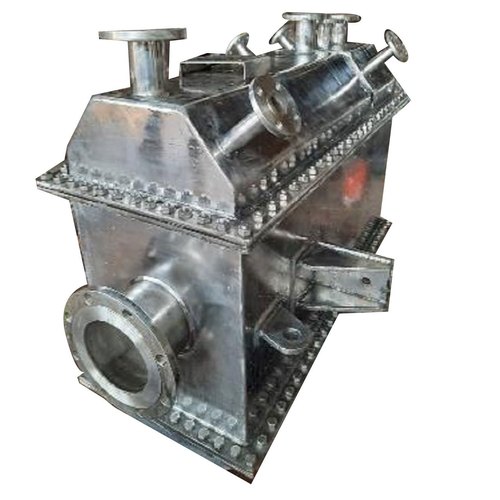

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Automatic |

| Material | Stainless Steel |

| Color | Available in Many Colors |

| Voltage | 440V |

| Warranty | 1 Year |

| Finishing | Polished |

| Weight | As Per Designed |

| Cooling Capacity | Higher Possesses More Partitions, Which Brings Better Efficiency |

| Cooling Time | Maximization of Cooling & Multi Separation is Achieved By More Number of Tubes and Lesser Length |

| Space | Occupies Less Space : for Instance, 15(12+3)m2 Box Type Heat Exchanger Occupies 700 X 500 Mm2 Area A |

| Descaling | Descaling Becomes Easy Since Tube Length is Ranging from 500mm to 600mm |

| Utility Charge | Cooling and Chilling Can Be Performed in Unison |

| International Standard | ASME. TEMA, ASHRAE, IBR, ASME-U-STAMP & R -STAMP |

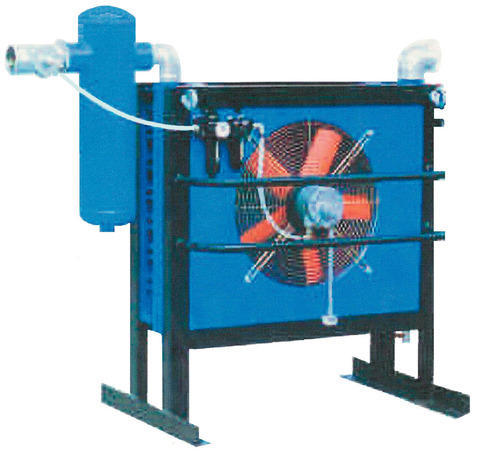

Fundamental Working and Purpose of Heat Exchanger

The heat exchanger is a system that helps transfer the heat into two or more fluids. Heat exchangers have their applications in both the heating and cooling processes. The fluids in the heat exchangers are kept separate with a solid wall in between them. One fluid's heat passes across the metal used to keep both of the fluids separate, and the heated metal then increases the other fluid's temperature. High turbulence, high fluid velocity, significant temperature differential, and high surface area; all these factors immensely contribute to efficient heat transfer. However, different designs can get tested for even better heat transfer, which prompted us to build Box Type Heat transfer that offers an improved heat transfer compared to the shell and tube type heat exchanger.

The manufacturing of Box Type Heat Exchanger includes state-of-the-art technology and compliance to international standards for manufacturing equipment. Experts check the heat exchanger's entire range on numerous parameters before dispatching it for the market's sales or sending it to the customer.

Here are some of its technical features:

Vapor loss ranges from 0.05% to 2% as per product

The flow rate remains 30% to 50%, depending on cooling media

Difference in temperatures T ranges from 2° C- 4° C as per product

The product's standard features include resistance against corrosion, surface finishing, and durability. To better understand this heat exchanger's versatility, let us compare it with other conventional heat exchangers.

| Business Type | Manufacturer, Exporter |

| Brand Name | FITZER,FITZER |

| Material | As per specification,STAINLESS STEEL, PLATINUM, AS PER SPECIFICATION |

| Finishing | AS PER SPECIFICATIONS |

| Shape | Rectangular |

| Color | As per specification,INDUSTRY STANDARD |

| Condition | New |

| Automation Grade | Manual |

| Usage | Industrial |

| Size | As per specification/Drawings,AS PER SPECIFICATIONS |

| Certification | ISO 9001:2015 |

| Width | As per Drawing/Specification |

| Dimension | SUBJECT TO DESIGN |

| Packaging Type | WOODEN PALLET |

| Outer Diameter | As per specifications |

| Working Pressure | from vacuum to 8.2MPa |

| Specialities | Resistant To Oil, Durable Finish Standards, Abrasion Resistance, high temperature and pressure resistance |

| Type | Plate Heat Exchanger,Plate Heat Exchanger |

| Thickness | As per Drawing/Specification |

| Weight | 150-200g |

| Working Temperature | -195℃ to 538℃ |

| Warranty | 1 YEAR AGAINST MANUFACTURING DEFECTS |

| Country of Origin | India,INDIA |

| Elongation | NA |

| Inside Diameter | NA |

| Operating Pressure | 300 MPa |

| Chemical Resistance | Yes |

| Surface | smooth and not easy to scale |

| unique corrugated design | the fluid to generate turbulent flow even at low flow rates, and has high heat transfer efficiency |

| non-metallic sealing material | high temperature and pressure resistance |

| Design & Salient Features | compact structure, efficient heat transfer and flexible use. |

| Product Code | FI-WPHE |

| Port | Mumbai & Gujarat |

| Payment Terms | T/T, Other |

| Delivery Time | 3-4 Weeks |

| Packaging Details | WOODEN PALLETS |

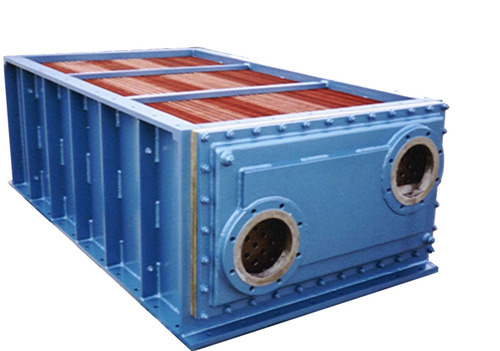

The heat exchange plate of the fully welded plate heat exchanger is made of special stainless steel and pressed with a special mold. The surface is smooth and not easy to scale. Its unique corrugated design enables the fluid to generate turbulent flow even at low flow rates, and has high heat transfer efficiency. No non-metallic sealing material is used, so it has high temperature and pressure resistance. It can be used for extreme working conditions with a working temperature of 300°C and a pressure of 3.0Mpa. The advantage is that it has a corrugated plate structure similar to the plate heat exchanger. At the same time, it adopts a more advanced all-welding process to seal, no gasket design, and a variety of metal and alloy materials to choose from, ensuring the applicable temperature of the all-welded plate heat exchanger. Almost all heat exchange process occasions from -195℃ to 538℃ and working pressure from vacuum to 8.2MPa. And it has the characteristics of compact structure, efficient heat transfer and flexible use.

| Business Type | Manufacturer, Exporter |

| Ratings | 1200 °F 1400 °F 1600 °F |

| Depth | As Per Model |

| Corrosion Resistance | Yes (Excellent Corrosion Resistance Against HCl,HF,H₂SO₄,HBr) Limited Resistance To Oxidizers Li |

| Maximum Working Pressure | Up To 6 Bar (standard) Higher On Request |

| Driven | THERMAL |

| Country of Origin | India |

| Warranty | ONE YEAR |

| Phase | NOT APPLICABLE |

| Frequency | NOT APPLICABLE |

| Weight | 500-1000 Kg,1000-2000 Kg,2000-2500 Kg |

| Thickness | Graphite Plate Thickness: 10–30 Mm Frame Thickness: As Required |

| Diameter | As Per Design Requirement |

| Type | GRAPHITE PLATE HEAT EXCHANGER,GRAPHITE PLATE AND FRAME HEAT EXCHANGER |

| Dimension (LxWxH) | AS PER REQUIREMENT |

| Production Capacity | AS PER REQUIREMENT |

| Technique | Isostatic Graphite Technology Post-impregnation CNC Machining Modular Plate & Frame Assembly PFA/ |

| Hardness | Graphite Plates: High Hardness, Machined After Impregnation |

| Packaging Type | Carton Box,Wooden Box,Metal Sheet Box |

| Operating Temperature | Up To 180°C (Depending On Process Fluid) |

| Voltage | NOT APPLICABLE |

| Grade | ASTM AISI Other |

| Certification | ISO 9001:2008 Certified CE Certified |

| Size | (Customizable Based On Plate Area) 5 Inches 10 Inches 15 Inches 20 Inches |

| Usage | Heat Transfer,Heat Transfer Chemical Process Cooling Hydraulic & Industrial Applications Acid Cooling & Heating |

| Medium used | Water Oil Air Acidic Media (HCl,HBr,HF,H₂SO₄) |

| Speciality | Reliable,Robust Construction,Easy To Use,High Efficiency,Reliable Robust Construction Easy To Use High Efficiency (2–3× Higher Than Conventional Exchanger |

| Power | NOT APPLICABLE |

| Automatic Grade | Manual |

| Condition | New |

| Color | Black (Graphite Plates) Grey Silver (SS Frame),BLACK |

| Shape | Rectangular (Plate Pack) Cylindrical (Inlet/Outlet Connections) Square (Frame) |

| Finishing | Galvanized (Frame) Polished Unpolished Coated (Anticorrosive) |

| Material | Graphite (Impervious / Isostatic) Stainless Steel (Frame) Mild Steel (Frame – Coated) Gun Metal /,GRAPHITE PLATES |

| Brand Name | FITZER |

| Design | Modular design for easy expansion |

| Surface | Smooth machined surface for maximum heat transfer |

| High Efficiency | High turbulence ensures superior thermal efficiency |

| Pressure Drop | Low pressure drop |

| Gasket | Leak-free operation using PTFE/Viton gaskets |

| Heat Transfer Area SQM | Customizable plate area (5 m² – 500 m²) |

| Media | Suitable for ultra-corrosive media |

| Footprints | Long service life with minimal maintenance |

| Product Code | FI-GPHE-900 |

| Port | Mumbai & Gujarat |

| Payment Terms | T/T, Other |

| Delivery Time | 3-4 Weeks |

| Packaging Details | Carton Box Wooden Box Metal Sheet Box |

Graphite Plate & Frame heat exchangers are designed to cool down or heat up ultra-corrosive chemicals. Safety, reliability, and performance in the long-term are our primary considerations when we size, design and manufacture our impervious graphite plate heat exchangers.

Key benefits:

Efficiency

2 to 3 times higher efficiency:

These units deliver 2–3 times greater efficiency compared to conventional heat exchangers, allowing for a much more compact design. The high internal turbulence significantly increases the film heat transfer coefficient, resulting in superior thermal performance.

Corrosion Resistance

Exceptional resistance to aggressive acids:

Our range of impervious graphite plate heat exchangers offers highly customized solutions for ultra-corrosive heat transfer applications. They provide excellent corrosion resistance to strong acids including HCl, HF, H₂SO₄, and HBr.

However, they exhibit limited resistance to oxidizing agents such as Cl₂ and high-concentration H₂SO₄ (above 65%), as well as caustic solutions like KOH and NaOH.

Modular Design

Ultra-compact and fully customizable:

Every impervious graphite plate heat exchanger is designed with a modular architecture, enabling precise adaptation to specific process requirements.

The number and dimensions of plates, along with process and service-side flow passes, can be customized to achieve optimal velocities, pressure drops, and heat transfer efficiency.

All graphite plates are precision-machined after impregnation, ensuring a perfectly smooth heat transfer surface and delivering excellent corrosion resistance along with long-term operational reliability.

Design:

Modular design: number of plates, size of plates and number of passes can be adjusted

Different plate sizes: GP 25 and GP 40

PTFE lined steel nozzles

Thermal expansion compensation ensured by helicoidal springs

MOC:

The material used for these heat exchangers is the same as that for block heat exchangers, with a high thermal conductivity of approximately 130 W/m.K.

GAB GPX 1, GPX 1T , or GPX 2 plates

Pressure plates and flanges: PTFE carbon steel

Tie rods, nuts, bolts, washers, springs: stainless steel

PTFE gaskets between the plates

Features:

Design pressure: up to 6 bars in standard

Design temperature: -30°C to +200°C (-22°F to 392°F)

Heat transfer area: up to 29m²

Nozzle sizes: DN80 / DN100 PN16

Design:according to European PED, ASME code on request

| Business Type | Manufacturer, Exporter |

| Number Of Flower | Automatic |

| Material | Mild Steel |

| Packaging Type | Sliver |

| Country of Origin | 380V |

| Total Carbohydrate | 1 Year |

| Finishing | Polished |

| Availability | As Per Designed |

| International Standard | ASME. TEMA, ASHRAE, IBR, ASME-U-STAMP & R -STAMP |

Kettle Reboiler Type Heat Exchanger is a retaining wall or overflow weir separating the tube bundle from the reboiler section where the residual reboiled liquid called the bottoms product, Kettle Reboiler Type Heat Exchanger bundle is kept covered with liquid.Kettle reboilers are reliable in that they can handle high vaporization of up to 80 percent and are easy to maintain. The liquid from the bottom of the tower flows through the tube bundle and exits as condensate. Kettle reboilers are very simple and reliable. Kettle Reboiler Type Heat Exchanger may require pumping of the column bottoms liquid into the kettle, there may be sufficient liquid head to deliver the liquid into the reboiler. Kettle Reboiler Type Heat Exchanger reboiler type, steam flows through the tube bundle and exits as condensate. The liquid from the bottom of the tower, commonly called the bottoms, flows through the shell side. A restraining device controls the liquid level over the bundle. The high level of vaporization makes it prone to fouling, and these reboilers are expensive due to their large shell size and maintenance.

Specifications :

- Kettle reboilers are heat exchangers typically used to provide heat to the bottom of industrial distillation columns.

- In a typical classical distillation column, all the vapor driving the separation comes from the reboiler.

- The reboiler receives a liquid stream from the column bottom and may partially or completely vaporize that stream. Steam usually provides heat required for the vaporization.

- Kettle reboilers the liquid from the bottom of a distillation column to generate vapors which are returned to the column to drive the distillation separation. Proper reboiler operation is effective distillation.

- The reboiler receives a liquid stream from the column bottom and may partially, completely vaporize that stream.

- Steam usually provides heat required for the vaporization.

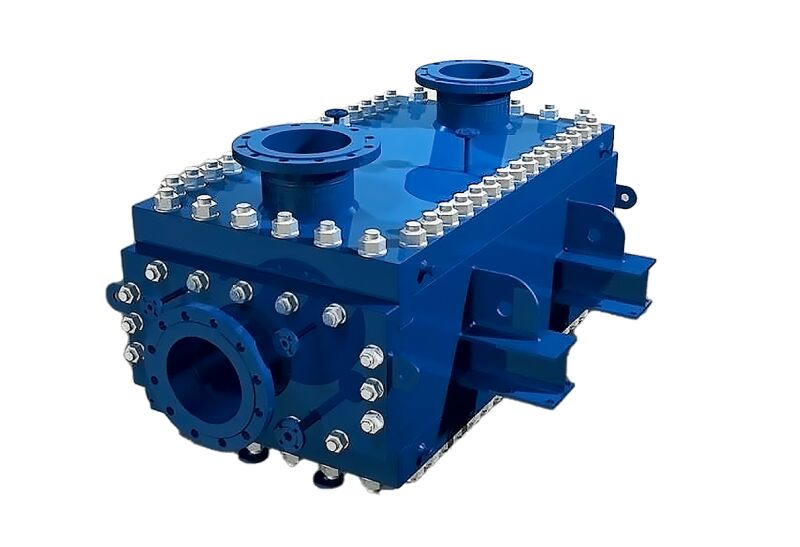

| Business Type | Manufacturer, Exporter, Supplier |

| Weight | As Per Designed |

| Size | 500 MM |

| Product Type | Paddy Dryer Heat Exchanger |

| Color | Silver |

| Structure | Tube Heat Exchanger |

| Voltage | 230-415 Volt (v) |

| Supply Ability | 1 Per Week |

| Tube Material | Steel |

| Application | Food Process Industry, Power Generation, Hydraulic and Industrial Process |

| International Standard | ASME. TEMA, ASHRAE, IBR, ASME-U-STAMP & R -STAMP |

Leveraging on rich expertise and advanced manufacturing facility, we are counted as one of the reckoned manufacturers and exporters of Paddy Dryer Heat Exchanger. Quality is our prime focus, hence we source tested quality materials from authentic vendors to manufacture these heat exchangers as per industrial standards. Finds application in chemical, oil and refinery plants, our Paddy Dryer Heat Exchanger is demanded among our clients for its impeccable performance, easy installation and rust proof finish.

Features of Paddy Dryer Heat Exchanger :

- Uniform and reliable heat transfer

- Rust proof body

- Hassle free installation

| Business Type | Manufacturer, Exporter |

| Catalog | |

| Finishing | SAND BLAST |

| Type | Heavy Duty |

| Material | Metal |

| Usage | Industrial |

| Voltage | 220 V |

| Warranty | 1 Year |

| Weight | As Per Designed |

| Brand Name | FITZER |

| International Standard | ASME. TEMA, ASHRAE, IBR, ASME-U-STAMP & R -STAMP |

| Plate material | Stainless steel (304, 316, 315J1, 317), titanium, high nickel alloy, nickel, or other standard materials |

| Gasket material | NBR, IIR, EPDM, FPM, silicon, or TCG (PTFE cushion gasket) |

| Working pressure | Up to 4.0 MPaG |

| Working temperature | Up to 180°C |

| Heat transfer area | 0.18 m2/unit to 3,400 m2/unit |

| Processing capacity | 0.1 m3/h to 7,300 m3/h |

| Plate thickness | Not less than 0.4 mm |

| Plate alignment | Interlocking mechanism pressed into each plate to ensure proper sealing |

| Product Code | FI-PHE- |

| Port | Mumbai & Gujarat |

| Payment Terms | T/T, Other |

| Delivery Time | 3-4 Weeks |

| Packaging Details | WOODEN & CORRUGATED |

Pillow Type Plate Heat Exchanger uses metal plates to transmit heat between two fluids and is available in different specifications. Also, using this modern solution has more advantages over conventional heat exchangers.

At FITZER, you will get the unparalleled quality at industry leading prices. Being one of the industry’s leading Plate Heat Exchanger Manufacturers in Gujarat - INDIA, We offer several specifications to choose from.Major Characteristics Of Plate Heat Exchanger Are:

- Simple And Compact Design: This Industrial Plate Heat Exchanger has a simple fabrication and comes in small and easy-to-use designs to fit in your industry premises. These thin sheets have corrugations and patterns to increase the surface area as well as the efficiency of the products.

- Quick To Clean And Maintain: These Heat Exchangers are made of good quality metal, which makes it easier to clean and maintain them after completing the application.

- Easy To Enhance The Capacity: You can simply expand the size and capacity of the sheet by just adding one along with others.

Application Areas:

- Steel Industry

- Marine Industry

- Pharma Industry

- Dairy Industry

- Beverage Industry

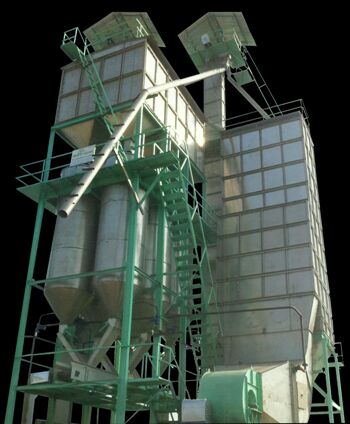

| Business Type | Manufacturer, Exporter |

| Brand Name | FITZER,FITZER |

| Material | As Per Specification/Drawings,SS, MS, ALUMINUM, AS PER REQUIREMENT |

| Finishing | As Per Requirement |

| Shape | Rectangular |

| Packaging Type | Wooden Box |

| Condition | New |

| Automatic Grade | Semi Automatic |

| Power | NA |

| Speciality | Reliable, Robust Construction, Easy To Use, High Efficiency, HIGH THERMAL EFFICIENCY |

| Medium used | OIL, WATER, AIR |

| Usage | Air, Heat Transfer, Hydraulic And Industrial Process, Paper Manufacture Industries,Printing Industries. RICE MILLS,Food Process Industry,Power Generation,Mining & Construction Industry,Pharmaceutical Industry |

| Size | As Per Specification/Drawings,AS PER DESIGN/REQUIREMENT |

| Certification | ISO 9001:2015 |

| Grade | ASTM |

| Country of Origin | India |

| Operating Temperature | AS PER REQUIREMENT |

| Hardness | DURABLE |

| Technique | NA |

| Production Capacity | 50 |

| Dimension (LxWxH) | AS PER REQUIREMENT |

| Number Of Flower | RICE MILL HEAT EXCHANGER,RICE MILL HEAT EXCHANGER,AIR COOLED |

| Diameter | NA |

| Thickness | AS PER DESIGN |

| Availability | 500-1000 Kg, 1000-2000 Kg |

| Frequency | NA |

| Phase | NA |

| Total Carbohydrate | 1 Year |

| Driven | PROCESS & UTILITY |

| Maximum Working Pressure | 300 Psi |

| Corrosion Resistance | Yes |

| Depth | AS PER REQUIREMENT |

| Ratings | AS PER DESIGN/REQUIREMENT |

| Inlet Temperature | as per requirement |

| Outlet Temperature | AS PER DESIGN/REQUIREMENT |

| Flow Rate (L/min) | AS PER DESIGN/REQUIREMENT |

| Maximum Working Pressure (in PSI) | 300 PSI |

| Product Code | FI-FTHE- |

| Port | Mumbai & Gujarat |

| Payment Terms | T/T, Other |

| Delivery Time | 3-4 Weeks |

| Packaging Details | WOODEN |

We are prominent manufacturers & suppliers of Rice mill Heat Exchangers from India. We are appreciated in the worldwide market and are offered at the competitive prices. We are able to maintain the trust and allegiance of our clients by constantly supplying products at par with international quality standards.

Product Details:

Application Food Process Industry, Power Generation, Hydraulic and Industrial Process, Mining & Construction Industry, Pharmaceutical industry

Medium Used Oil, Water, Air

Inlet Temperature as per requirement

Type Air-Cooled

Outlet Temperature as per requirement

Flow Rate (L/min) as per requirement

Maximum Working Pressure (in PSI) 300 psi

Rice Mil

Furthermore, the range is used in the following:

Heat Recovery project.

Paper manufacture industries.

Printing industries.

Wet processing machinery for textile industries.

Plywood industries.

Food processing Industries.

Chemical & fertilizer industries.

| Business Type | Manufacturer, Exporter |

| Catalog | |

| Country of Origin | 380V |

| Certification | ISO 9001:2008 |

| Availability | As Per Designed |

| Packaging Type | Available In Many Colors |

| Condition | New |

| Automatic Grade | Manual |

| Power | NA |

| Design Code | IS-4503, IS-2825, AMSE SEC. VIII, TEMA, BS-5500, HEI, API-660 |

| Number Of Flower | Fixed Tube Sheet, Removable tube Bundle, U-Tube, Coil in Tank, double Pipe |

| Capacity Range | As per clients requirement |

| Shell Diameter | 4″ to 125″ |

| Tube Length | 3′ to 40′ |

| Tubes | Plain, Corrugated, Integrally Finned or U-Tubes |

| M.O.C. Tubes | Carbon Steel, Stainless Steel, Copper, Adm. Brass, Aluminium, Titanium, Tantalum, Hastolloy, Allumin |

| Shell | Carbon Steel, Stainless Steel, Copper, Monel. Brass, Aluminum |

| International Standard | ASME. TEMA, ASHRAE, IBR, ASME-U-STAMP & R -STAMP |

| Product Code | FI-STHE- |

| Port | Mumbai & Gujarat |

| Payment Terms | T/T |

| Delivery Time | 3-4 Weeks |

| Packaging Details | WOODEN |

- We manufacture Shell & Tube type Heat Exchangers in a wide variety of sizes & materials. We have a complete facility to design (Thermal and Mechanical) and manufactures complete range of Shell and Tube Heat Exchangers for cooling, condensing and heating application.

- A Shell & Tube Heat Exchanger Consists of a Shell with Traditional plain tubes or enhanced surface tubes for high thermal performance.

- Our manufacturing facility is well supported by in house design facility equipped with latest software’s & design codes and welding development department to establish manufacturing process for any new material.

| Business Type | Manufacturer, Exporter |

| Brand Name | FITZER |

| Material | Stainless Steel |

| Finishing | Coated |

| Shape | Cylindrical |

| Packaging Type | Wooden Box |

| Condition | New |

| Automatic Grade | Manual |

| Power | NOT APPLICABLE |

| Speciality | Reliable, Robust Construction, Easy To Use, High Efficiency, Counter Current And Co Current Flow |

| Medium used | WATER, SLURRY LIQUID |

| Usage | Water, Oil, Air, Heat Transfer, Hydraulic And Industrial Process, HIGH THERMAL EFFICIENCY |

| Size | As Per Specification/Drawings |

| Certification | ISO 9001:2008 Certified |

| Grade | ASME, API, TEMA, PED |

| Country of Origin | India |

| Operating Temperature | -100 DEG C TO 500 DEG C |

| Hardness | METAL |

| Technique | Counter Current And Co Current Flow |

| Production Capacity | 5 Units Per Month |

| Dimension (LxWxH) | As Per Designed |

| Number Of Flower | Spiral Heat Exchanger |

| Diameter | 300 MM & ABOVE |

| Thickness | 2MM TO 50 MM |

| Availability | As Per Designed |

| Phase | NOT APPLICABLE |

| Total Carbohydrate | 1 Year |

| Driven | BY PROCESS |

| Flow Rate | 5 LPM AND ABOVE |

| Maximum Working Pressure | 45 BAR & ABOVE |

| Corrosion Resistance | Yes |

| Depth | AS PER DESIGN |

| Ratings | -100 DEG C TO 500 DEG C |

| Outlet Temperature | AS REQUIRED |

| Inlet Temperature | -100 DEG C AND ABOVE |

| International Standard | ASME. TEMA, ASHRAE, IBR, ASME-U-STAMP & R -STAMP |

| LIFE SPAN | 20 YEARS & MORE |

| Product Code | FI-SHE-900 |

| Port | Mumbai & Gujarat |

| Payment Terms | T/T |

| Delivery Time | 3-4 Weeks |

| Packaging Details | WOODEN |

The spiral plate heat exchanger is made by rolling two long metal plates around a center core to form two concentric spiral flow passages, one for each fluid. The plate edges are welded shut so that each fluid stays within its own passage and there is no flow bypassing or intermixing. Channel plate width and spacing (gap between plates) are optimized for the specified duty, maximum heat transfer, and ease of access. The plate gap is maintained by welded spacer studs although some designs do not require them.

Due to its inherent circular design and large surface area to volume ratio, the spiral heat exchanger offers unique advantages over other types of heat exchangers like the shell and tube.

Single and long curving flow passages with a uniform rectangular cross-section ensure superior flow distribution, intense turbulence, and high heat transfer coefficients (50-100% greater than shell & tubes).

Self-Cleaning PassagesThe spiral's single-flow passages induce high shear rates that scrub away deposits as they form. This self-cleaning effect reduces fouling and makes spiral heat exchangers ideal for handling tough fluids such as process slurries, sludge, and media with suspended solids or fibers.

Countercurrent or Co-currentSpiral heat exchangers normally operate in true countercurrent flow for close approaches and temperature crosses. Occasionally a co-current flow design has major benefits, especially in cooling or heating fluids prone to gelation, burn-on, freezing or similar skin temperature related fouling.

Small Footprint & Easy AccessThe spiral heat exchanger is compact and requires minimal space for installation and servicing. Removable covers provide easy access to interior heat transfer surfaces for field inspections, routine maintenance, or manual cleaning if required.

| Business Type | Manufacturer, Exporter |

| Number Of Flower | Tube in Tube |

| Material | Stainless Steel |

| Certification | International Standard |

| Packaging Type | Sliver |

| Country of Origin | 220V |

| Total Carbohydrate | 1 Year |

| Shape | Cylindrical |

| Availability | As per designed |

Our range of Corrugated Tube Heat Exchangers use corrugated Tubes to enhance heat transfer. Two types of heat exchanger are available. The mono-tube design has a single tube within a tube and the multi-tube design has a number of tubes inside a shell.

Each design has variants for either industrial or hygienic applications.

The construction can be either all welded or with removable tubes for ease of maintenance.

Advantages:- Higher thermal efficiency due to corrugated tubes

- Easy to clean

- Low maintenance

- Product side in AISI 316, AISI 316L, Duplex steels

- Service side in AISI 304

- Other materials available on request

- Stainless steel frame

- Thermal insulation

| Business Type | Manufacturer, Exporter |

| Number Of Flower | Automatic |

| Material | Stainless Steel |

| Packaging Type | Sliver |

| Country of Origin | 220V |

| Total Carbohydrate | 1 Year |

| Shape | Cylindrical |

| Availability | As Per Designed |

| International Standard | ASME. TEMA, ASHRAE, IBR, ASME-U-STAMP & R -STAMP |

U Tube bundle Heat Exchanger can build "U" tube bundles, straight tube "floating" tube bundles, or we can retube fixed tubesheet heat exchangers when the bundles is not removable and multitherm is not locked into any one material. Heat-exchanger system consisting of a bundle of U tubes hairpin tubes surrounded by a shell outer vessel, one fluid flows through the tubes, and the other fluid flows through the shell, around tubes.Multitherm can duplicate any existing bundle to include dimensions, materials and performance.Some bundles tend to be build with copper tubes and steel tubesheets. U Tube bundle Heat Exchanger of each tube are connected to plenums (sometimes called water boxes) through holes in tubesheets. The tubes may be straight or bent in the shape of a U, called U-tubes.

Specifications :

- U Tube bundle Heat Exchanger which typically have U-tubes.

- U Tube bundle Heat Exchanger can be used to boil water recycled from a surface condenser into steam to drive a turbine to produce power.

- Most U Tube bundle Heat Exchanger are either 1, 2, or 4 pass designs on the tube side.

- This refers to the number of times the fluid in the tubes passes through the fluid in the shell.

Applications :

- U Tube bundle Heat Exchanger fluid goes in one end of each tube and out the other.Surface condensers in power plants are often 1-pass straight-tube heat exchangers see Surface condenser for diagram.

- U Tube bundle Heat Exchanger are two and four pass designs are common because the fluid can enter and exit on the same side. U Tube bundle Heat Exchanger construction much simpler.

- U Tube bundle Heat Exchanger are often baffles directing flow through the shell side so the fluid does not take a short cut through the shell side leaving ineffective low flow volumes.

- U Tube bundle Heat Exchanger are generally attached to the tube bundle rather than the shell in order that the bundle is still removable for maintenance. Counter current heat exchangers are most efficient and they allow the highest log mean temperature difference between the hot and cold streams.

- U Tube bundle Heat Exchanger companies however do not use single pass heat exchangers and they can break easily in addition to being more expensive to build.

- Often multiple heat exchangers can be used to simulate the counter current flow of a single large exchanger.

Advantages :

- The simple design of a shell & tube heat exchanger makes it ideal cooling solution for a wide variety of applications.

- One of the most common applications is the cooling of Hydraulic Fluid and oil in engines, transmissions and hydraulic power packs.

- With right choice of materials they can also be used to cool or heat other mediums,

- Particularly with models where a floating tube bundle (where the tube plates are not welded to the outer shell) is available. Can also be used on fixed tube sheet heat exchangers.

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Stainless Steel |

| Air Flow | 200 Scfm |

| Usage | Industrial |

| Voltage | 220V |

| Weight | As Per Designed |

| Warranty | 1 Year |

| Blower/Fan | Yes |

| Country of Origin | India |

| Material of Construction | Size ranging from 80mm to 2500mm in diameter & 12 meter in length |

| EFFICIENCY | 99%. |

| Size | As per Requirement |

| DESIGN AS PER | ASME Section VIII Div. 1, Div. 2, TEMA API 660, 661, IS 2825 & IS 4503 |

| PRESSURE DROP | less than 250-500 mm WC |

| International Standard | ASME. TEMA, ASHRAE, IBR, ASME-U-STAMP & R -STAMP |

| Tubes: | 90/10 Cupronickel, 70/30 Cupronickel, Copper Stainless Steel - 304, 304L, 316, 316L Al. Brass As per customer requirement |

| Tube Sheet: | 90/10 Cupronickel, 70/30 Cupronickel, Carbon steel, Naval Brass Stainless Steel - 304, 304L, 316, 316L Hastolly Inconel Monel |

| Channels / Headers/ End Covers: | Cupronickel Nickel Aluminum Bronze Gunmetal-Naval Grade Graded Cast iron Carbon steel Stainless Steel - 304, 304L, 316, 316L Hastolly Inconel Monel |

| Certification | International Standard |

After cooler:

Water or moisture is not desirable in the transmission lines of an air compression system. Water carried through the lines washes away lubricating oil from the tools the compressed air is running. This causes the tools to operate sluggishly & increases the need for maintenance. The effect is compounded in high speed tools, where wearing surfaces are limited in size & excessive wear reduces efficiency by creating air leakage.

Further problem results from the decrease of temperature caused by sudden expansion of air at the end. This low temperature creates condensation, which freezes around port and valves & impairs efficiency. These conditions can be minimized by removing the moisture from the air directly after compression, before the air enters the distribution system.

The compressed air discharged from compressor is hot. Compressed air at these temperatures contains large quantities of water in vapor form. As the compressed air cools this water vapor condenses into a liquid form. As an example if an after cooler is not used, a 200 scfm compressor operating at 100 psig introduces 45 gallons of water into the compressed air system each day.

Functions of compressed air after coolers

-

Cool air discharged from air compressors via the heat exchanger

-

Reduce risk of fire (Hot compressed air pipes can be a source of ignition)

-

Reduce compressed air moisture level

-

Increase system capacity

-

Protect downstream equipment from excessive heat

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Stainless Steel |

| Number of Fan Blades | 3, 4 |

| Usage | Industrial |

| Color | Silver |

| Voltage | 220V |

| Weight | As Per Designed |

| Warranty | 1 Year |

| Efficiency | 99% |

| PRESSURE DROP | less than 250-500 mm WC |

| International Standard | ASME. TEMA, ASHRAE, IBR, ASME-U-STAMP & R -STAMP |

Inter cooler:

Most industrial compressors operating today are a multistage design. To optimize the cost of compressing gases it is popular to use multi-stage industrial compressor. When the Air compressor compresses air, heat is generated this causes the air to expand requiring an increase of horsepower for further air compression. If we remove the heat generated by compressing air, the total horsepower required for addition air compression is reduced up to 15%. For a multi stage compressor is to cool the gas between compression stages. Thus the role of the compressor intercooler is to provide colder, dryer, denser air to the next stage of compression. In addition to inter stage coolers, the compressor's final discharge is usually routed through an after cooler, which also provides colder and dryer gas to the end use point.

We provide Intercooler to suit compressor mounting by maintaining critical nozzle distance, as well as side mountings with volume bottles to avoid pulsation.

EFFICIENCY

Moisture Separator are largely used for the separation of coarse mist (or spray) from gases and vapors. A limit drop size (Dp) is used to characterize them and it is defined as the smallest particle which can be removed to an extent of 99%.

PRESSURE DROP

Due to the large percentage of the cross section available for gas flow, the pressure drop in a vast majority of applications is less than 250-500 mm WC. As mentioned above, for high efficiency applications, a larger pressure drop is to be expected.

.

|

Thermal Calculation are done on the based on suction condition

|

|

|

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Automatic |

| Material | Copper Nickel Tubes |

| Application | Industrial |

| Voltage | 380V |

| Power | 1-3kw |

| Warranty | 1 Year |

| Brand Name | FITZER |

| High fin stability, excellent heat transfer, high operating temperature. The fin/tube wall contact is constant because of the setting and makes it possible to use a wall temperature of up to 450°C. | The fin is set throughout its length and consequently does not unwind even when partially uprooted. This kind of finned tube is one of optimum choices for having good effectiveness/cost ratio. |

| Weight | As per designed |

| International Standard | ASME. TEMA, ASHRAE, IBR, ASME-U-STAMP & R -STAMP |

| Payment Terms | T/T |

CHARGE AIR COOLERS are suitable for a variety of applications including Marine engine and Generator cooling. The Charge Air Coolers can be adapted for use on marine and land based equipment in a variety of sizes.

We are offering an assortment of charge air coolers which are known for their excellent industrial worth and effective uses. Our products offers quality and durable life with the promise of the full utility of the various types of integrated pattern engineering advances we have made in the recent times. We use high technology and anti-corrosive factors to increase the overall worth of our units by a great length. Our products could be used for all sorts of backgrounds and moisture laden working conditions. We customize and package them as per customers' demands. With the help of our R & D department we manufacture client centric products and deliver them at cost effective price.

- Variety of sizes available to suit a wide range of applications.

- Variety of materials for industrial and marine use.

- Completely customized cooler.

| Business Type | Manufacturer, Exporter |

| Number Of Flower | Automatic |

| Material | Steel |

| Application | Industrial |

| Packaging Type | White |

| Size | Standard |

| Weight | As per designed |

| International Standard | ASME. TEMA, ASHRAE, IBR, ASME-U-STAMP & R -STAMP |

With engine efficiency constantly improving, the demand for more efficient oil cooling has never been greater. Bowman is a leading UK manufacturer of efficient, durable oil coolers for both industrial and marine engines and transmissions. Designed specifically for lubrication oil cooling, these high-quality units can be used with engines rated up to 8900 kW and are suitable for use with a range of cooling media, including sea water, fresh water or engine coolant.

- Compact design Easily installed and integrated with the engine

- Premium quality UK manufactured, using quality components

- Easy product selection Available quickly from our technical experts

- Rapid delivery Extensive stockholding for fast response

- Wide range Suitable for engines rated from 20 kW to 8900 kW

- High performance Models are available for up to 30 bar oil pressure

| Business Type | Manufacturer, Exporter |

| Number Of Flower | Two Pass / Four Pass |

| Application | Reheat Furnaces, Large Forging Furnaces, High Temperature Kilns. |

| Finishing | Polished |

| Warranty | 1 Year |

| Construction | Tubular |

| Material | SS 310 / SS 304/ Carbon Steel |

| Mounting | Underground / Above ground |

| Air Flow | Unidirectional Flow / Cross Flow |

| Weight | As per designed |

| International Standard | ASME. TEMA, ASHRAE, IBR, ASME-U-STAMP & R -STAMP |

| Business Type | Manufacturer, Exporter |

| Number Of Flower | Fabricated |

| Material | Aluminium, Mild Steel |

| Shape | Round |

| Packaging Type | Grey |

| Condition | New |

| Pressure | 15-30bar |

| Surface Finishing | Polished |

| Total Carbohydrate | 1 Year |

| International Standard | ASME. TEMA, ASHRAE, IBR, ASME-U-STAMP & R -STAMP |

| Availability | As per designed |

Vessels & Tanks :- We Design, Engineering and manufacture customized Vessels and Tank with various material of construction line MS, SS 304, SS 316L, FRP coated or MS Rubber Lined, PTFE lined and many more. We are working with nos. of OEM for their routine requirement of vessels and tanks in their projects.

Reactors:- Reactor Vessel is the heart of process of any industry. We offer customized design (process and mechanical) and do fabrication in our own workshop as per Good Engineering Practice as well as for ASME codes also.

We deal in all types of reactor vessel like jacket, non jacketed , agitated and limped. We also deal in pillow plate jacket reactor vessel also which provided high heat transfer with low operating cost and capital cost too.