Ankleshwar Gidc, Gujarat

- GST NO. : 24ACNPC1767D1ZW

Mobile : View Mobile Number

| Business Type | Manufacturer, Exporter |

| Brand Name | FITZER |

| Material | Stainless Steel,SA 240 TP304 SA 240 TP316/L SA 240 TP316TI SA 240 S31254 (SMO-254) HC-276 (HASTELLOY) SB 265 GR. 1, GR. 2 (TITANIUM) SA 265 GR. 11 (TI-PALLADIUM) NICKEL 200 / 201 |

| Finishing | Coated |

| Click to view more | |

Product Details

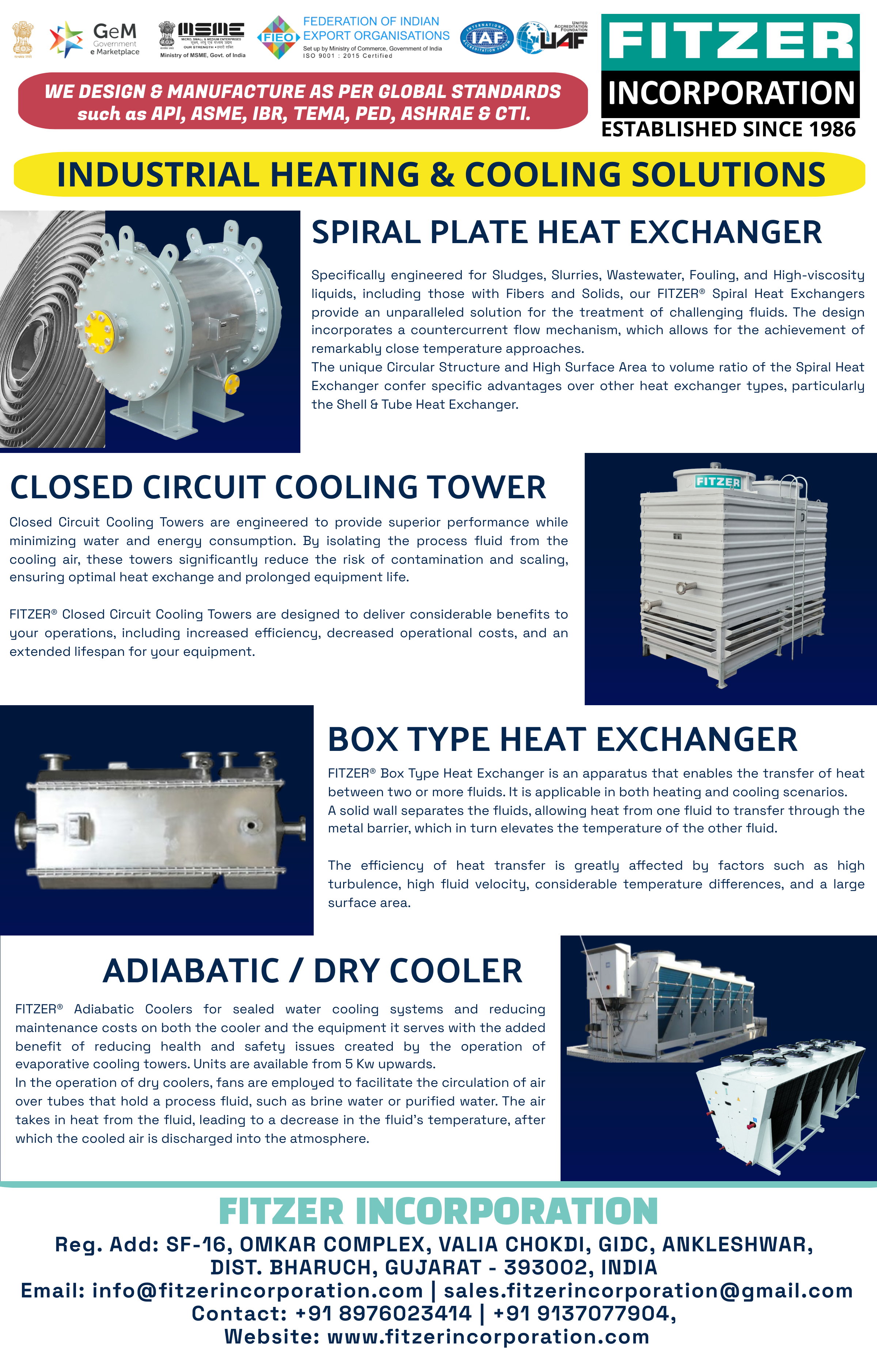

Bloc Type Welded Plate Heat Exchanger is made up of plate pack and frame. The plate pack is formed by welding a certain number of plates, then it is installed into a frame, which is configured by four corner girders, top and bottom plates and four side covers.

Welded Block Plate Heat Exchangers deliver high heat-transfer efficiency in a compact footprint, ideal for high pressure / high temperature and aggressive media where gasketed plate exchangers are not suitable.

We manufacture and supply Welded Block Plate Heat Exchangers designed for demanding process duties in chemical, petrochemical, refinery, and power applications. The plate pack is fully welded (gasket-free), enabling safe operation with high pressures, high temperatures, and corrosive fluids. Its compact design reduces space requirement and improves thermal performance compared to conventional shell & tube in many duties.

Key Benefits

-

Gasket-free welded construction (low leakage risk)

-

Handles higher pressure/temperature than gasketed PHE

-

High turbulence → high heat transfer coefficient

-

Compact, low hold-up, faster response

-

Suitable for fouling / aggressive services (design dependent)

Specification:

-

Material: SS304 / SS316 / SS316L / Duplex / Titanium / Hastelloy (as required)

-

Shape: Rectangular Block / Skid Mounted Assembly (as applicable)

-

Capacity: As per duty (Heat Load) / Flow rate (custom)

-

Temperature Range: -20°C to 350°C (typical; as per design)

-

Brand Name: FITZER

-

Condition: New

-

Voltage: Not Applicable (Heat Exchanger)

-

Type: Welded Block Plate Heat Exchanger

-

Construction: Fully welded plate block (no gaskets in plate pack)

-

Flow Arrangement: Counter-current / Parallel / Multi-pass (as required)

-

Design Pressure: Up to 45 bar (custom)

-

Test Pressure: 60 bar

-

Design Temperature: Up to 150 to 450 °C (custom)

-

Heat Transfer Area: 4 to 865 m² (as per duty)

-

Connections: Flanged / ANSI / DIN / BS (as required)

-

Media: Water, oil, chemicals, solvents, refrigerants (compatibility as per MOC)

- Gasket: AFLAS, GRAPHITE, KLINGERSIL

-

Mounting: Floor / Skid mounted, lifting lugs provided

-

Testing: Hydro test, pneumatic/leak test as per standards

-

Standards: As per customer specification / applicable codes

- Applications: Heater, cooler, condenser, evaporator, heat recovery, interchanger

-

Industries: Chemical, Petrochemical, Refinery, Power, Pharma, Food (as suitable)

-

Advantages: Compact, high efficiency, low maintenance, leak-safe design

-

Optional: Insulation, vent & drain, instrumentation nozzles, bypass line, skid piping

welded block plate heat exchanger, welded plate heat exchanger, block type heat exchanger, gasket free plate exchanger, compact heat exchanger, high pressure heat exchanger, chemical heat exchanger, heat recovery exchanger

Looking for "Welded Plate Heat Exchanger" ?

Explore More Products

Our Blogs