Ankleshwar Gidc, Gujarat

- GST NO. : 24ACNPC1767D1ZW

Mobile : View Mobile Number

Heating Process Equipment

Leading Manufacturers, Exporters and Wholesaler of immersion water heater, Steam Accumulators, Heavy Fuel Oil Heater, Hot Air Heater, Hot Water Heater, Super Heater, Thermal Fluid Heater, Steam Boiler, Energy Plant and Fin Tube Economizer from Ankleshwar.

| Business Type | Manufacturer, Exporter |

| Material | Sheath Material starting from SS304, 321 COPPER, SS 316.,SS304 TUBES |

| Brand Name | FITZER,FITZER |

| Color | Red |

| Condition | New |

| Automatic Grade | Automatic, Manual, Semi Automatic |

| Power | 3000 W |

| Power Source | Electricity |

| Application | Radiant Heating Dies and Manifolds. Immersion Heating. Solar. Textile Industry |

| Certification | CE Certified, ISO 9001:2015 |

| Voltage | As per specifications |

| Temperature Capacity | 100-150C, 150-200C, 25-50C |

| Type | Water Immersion Heaters,Immersion Water Heater |

| Weight | 10-0kg |

| Warranty | 1year |

| After-Sales Service Provided | yes |

| Country of Origin | India,INDIA |

| Energy source | Electric |

| Size | Customized Size & Design |

| Insulation | MGO Insulation |

| Design | Precisely design with uniform heat distribution. |

| Connection | Brass as well M.S. & SS flanges IS available. |

| Durability | High Strength |

| Brazing | Silver |

| Product Code | FI-IWH- |

| Port | Mumbai & Gujarat |

| Payment Terms | T/T, Other |

| Delivery Time | 3-4 Weeks |

| Packaging Details | Corrugated & Wooden |

Immersion Heaters, These heaters are available in wide selection of rates, sizes and sheath materials suitable for the heating requirements of oil, water, and Chemical. Moisture resistant and explosion proof models are also available. All immersion heaters we offer you, including heaters for hazardous locations.

Features:

- Sheath Material starting from SS304, 321 COPPER, SS 316.

- MGO Insulation.

- Precisely design with uniform heat distribution.

- High Strength.

- CUSTOMIZED SIZE & DESIGN

- Brass as well M.S. & SS flanges IS available.

- Silver Brazing.

Industries & Applications:

- Radiant Heating

- Dies and Manifolds.

- Immersion Heating.

- Solar.

- To Heat Up water in any Industries.

- Textile Industries.

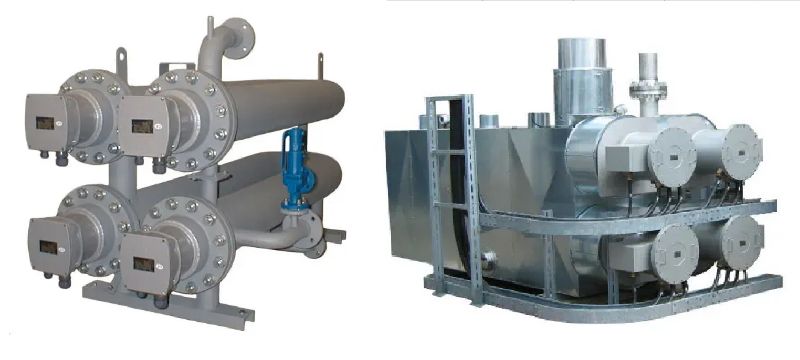

| Business Type | Manufacturer, Exporter |

| Driven Type | Mechanical, Pneumatic |

| Color | Grey, INDUSTRIAL GRADE |

| Condition | New |

| Power | As Per Plant Capacity |

| Automation Grade | Automatic, Manual, Semi Automatic |

| Application | Industrial Use, Steam Accumulator Is A Type Of Energy Storage Device |

| Certification | CE Certified, ISO 9001:2008, IBR APPROVED - NON IBR |

| Voltage | NA - STEAM STORAGE TANK |

| Type | Accumulator,STEAM ACCUMULATORS,STEAM ACCUMULATORS |

| Weight | AS PER CAPACITY |

| Warranty | 1year, 2years |

| Country of Origin | India,India |

| Brand | FITZER |

| Material | STAINLESS STEEL, TITANIUM, AS PER REQUIREMENT |

| Size | AS PER PLANT CAPACITY |

| Excellent performance | High operational frequency |

| Quality tested | Operated at optimum efficiency |

| Product Code | FI-SA- |

| Port | Mumbai & Gujarat |

| Payment Terms | T/T, Other |

| Delivery Time | 3-4 Weeks |

| Packaging Details | WOODEN |

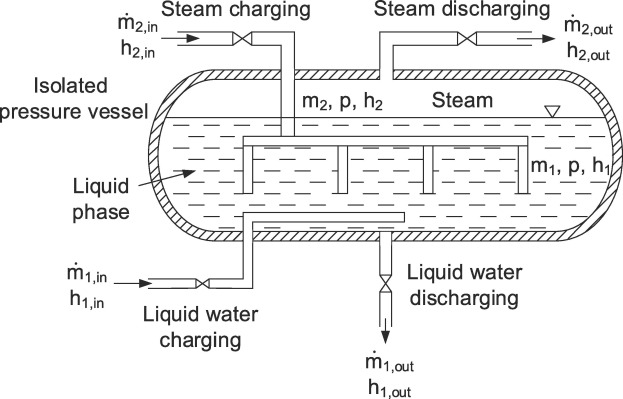

Steam Accumulator is a pressure tank made up of steel contain hot water and steam under pressure steam accumulator is a type of energy storage device. Accumulators are modern boilers are small in size, Efficient and high responsive change in loads. Steam accumulators is an extension of the energy storage capacity of boilers, steam boilers have a certain capacity for producing and supplying steam. For example: when the demand for steam from the plant is low and the boiler can generate more than required steam the excess steam is introduced into a mass of water stored under pressure.

FUNCTION OF STEAM ACCUMULATOR

Steam Accumulator is a pressure tank made up of steel contain hot water and steam under pressure steam accumulator is a type of energy storage device. Accumulators are Morden boilers are small in size, Efficient and high responsive change in loads.

Excellent performance

High operational frequency

Quality tested

Operated at optimum efficiency

USES OF STEAM ACCUMULATOR

Steam Accumulator is a pressure tank made up of steel contain hot water and steam under pressure steam accumulator is a type of energy storage device. Accumulators are modern boilers are small in size, Efficient and high responsive change in loads. Steam accumulators is an extension of the energy storage capacity of boilers, steam boilers have a certain capacity for producing and supplying steam. For example: when the demand for steam from the plant is low and the boiler can generate more than required steam the excess steam is introduced into a mass of water stored under pressure.

DESIGNING SPECIFICATION FOR STEAM ACCUMULATOR

Accumulator is constructed in the form of cylindrical, horizontal steel tank type of the tanks are based on the customer requirement and application. Data required for Steam Accumulators are as fallows

Capacity

Flow rate

Temperature

Charging pressure

Discharging pressure

| Business Type | Manufacturer, Exporter, Supplier |

| Type | HFO |

| Voltage | 380V |

| Application | Industrial Use |

| Warranty | 1 Year |

| Material | Stainless steel |

| Color | Silver |

| Finishing | Polished |

| Weight | As per designed |

| International Standard | ASME. TEMA, ASHRAE, IBR, ASME-U-STAMP & R -STAMP |

Heavy Fuel Oil (HFO) is the alternative fuel to Natural Gas commonly used in vast areas of the world where it is largely available

In some case HFO is used as alternative and in combination with NG in dual fuel furnaces, when the price of NG is subject to season fluctuations.

Compared with NG, the HFO is more critical to manage and needs space for reception, storage, treatment and distribution.

When designing our HFO combustion systems we keep into consideration all critical aspects of the fuel and the environmental conditions where the furnace operates.

The typical composition of our HFO combustion systems is:

- Main HFO storage

- Preheating and filtering/pumping system

- Main line distribution

- Heating and straining unit

- Dosing and pumping unit

- Reversal unit

- Compressed air section

As the quality of HFO can vary, in order to guarantee the maximum flame stability in the furnace the HFO heating and straining is accurately controlled. Strainers help in clarifying the fuel oil and removing large size impurities from the fuel oil system. The HFO dosing is controlled precisely as each burner will deliver constantly the same amount of fuel thus avoiding flame asymmetry within melting tank.

Both air and HFO are controlled and modulated continuously keeping stable Air / HFO ratio at any furnace load thus ensuring better efficiency.

Related arguments:

| Business Type | Manufacturer, Exporter |

| Number Of Flower | Automatic |

| Application | Industrial |

| Availability | As Per Designed |

| Country of Origin | 220V |

| Power | 3-6kw |

| Driven Type | Electric |

| Total Carbohydrate | 1 Year |

| Size | Standard |

| Frequency | 50 Hz |

| Phase | Single Phase |

| International Standard | ASME. TEMA, ASHRAE, IBR, ASME-U-STAMP & R -STAMP |

Our highly dedicated and devoted team of professionals enables us to manufacture and supply a wide assortment of Hot Air Generator.

Features:

- Modular design for easy transport & installation

- A fully safe & covered body designed to prevent dust

- Operated by Single / Three phase electric motor

Specifications:

- Fuel: Solid fuel fired, Oil & Gas fuel-fired

- Product Name: Hot Air Generator

- Condition: New

| Business Type | Manufacturer, Exporter |

| Number Of Flower | Automatic |

| Application | Boiling Water |

| Availability | As Per Designed |

| Country of Origin | 220V |

| Power | 1-3kw |

| Driven Type | Electric |

| Total Carbohydrate | 1 Year |

| International Standard | ASME. TEMA, ASHRAE, IBR, ASME-U-STAMP & R -STAMP |

TPC-AS is a vertical fired, coil type Hot Water Boiler designed for operation with water at high pressure and temperature. The concentric coils, flame reversal combustion chamber and three full gas pass configuration ensures high efficiency and very safe and simple operation.

TPC-AS is fitted with a Babcock Wanson burner specifically developed for this duty and perfectly matched to the combustion chamber for high efficiency, low emission operation. Burner control can be simple two stage or fully modulating control depending on the process requirements.

High Efficiency Coil Type Hot Water Boiler

- The TPC-AS configuration with large heat exchange surface and integral combustion air preheater ensures a thermal efficiency of up to 90% in standard form.

- TPC-AS includes an integral, air cooled outer case that acts as a combustion air pre-heater/economiser. This design also provides for efficient insulation of the boiler shell.

Robust Equipment

- The TPC-AS Hot Water Boiler is robustly built for long life and reliable operation.

- Test pressure up to 25 barg and water operating temperature up to 220°C.

- The TPC-AS configuration ensures safe, simple operation in the most demanding of environments.

Simple Reliable Operation

- TPC-AS includes an integral monobloc burner, combustion and system controls and standard safety equipment, all mounted and pre-wired.

- The TPC-AS Hot Water Boiler is delivered to site ready for connection to the fuel system, electrical power, chimney and water system for fast site installation.

- Refractory within the combustion chamber has been reduced to a minimum for long life and simple maintenance.

Environmentally Friendly

- Babcock Wanson burners have been designed to meet all normal environment standards. They optimise fuel consumption and are easy to maintain.

- Flue gas emissions in accordance with European regulations.

Full Range of Ancillary Equipment

- System design and project management

- System ancillaries and heat exchangers

- Installation and piping service

- Supply and Commissioning

| Business Type | Manufacturer, Exporter |

| Number Of Flower | Super |

| Material | Cast Iron, Iron, Steel |

| Certification | CE Certified |

| Application | Industrial |

| Country of Origin | 440V |

| Power | 3-6kw |

| Power Source | Electric |

| Total Carbohydrate | 1 Year |

| International Standard | ASME. TEMA, ASHRAE, IBR, ASME-U-STAMP & R -STAMP |

| Weight | As per designed |

A SUPER HEATER is a device used to convert saturated steam or wet steam into super-heated steam or dry steam. There are three types of super heaters : 1. RADIANT SUPER HEATER : Placed directly in the combustion chamber. 2. CONVECTIVE SUPER HEATER : Located in the path of the hot gases. 3. SEPARATELY FIRED SUPER HEATER : Totally separated from the boiler. We at SGM TECH design and manufacture all types of super heaters. We study the client's requirements and design the most optimum solution by adopting best engineering methods.

| Business Type | Manufacturer, Exporter |

| Type | Automatic |

| Material | Alloy Steel, Mild Steel |

| Certification | 9386548 |

| Application | Industrial |

| Weight | As Per Designed |

| Power Source | Thermal Power |

| Voltage | 440 V |

| International Standard | ASME. TEMA, ASHRAE, IBR, ASME-U-STAMP & R -STAMP |

A thermic fluid heating system generally used in a system where the pressure is not desired in a process and temperature requirement is higher and using the boiler for high-temperature services may increase the cost of a project.

Thermal Fluid Heaters can improve process consistency and reduce downtime leading to a further increase in profitability.

Industrial Applications of Thermic Fluid Heaters

Thermic fluid systems can be used to generate heat in various process industries, such as:-

- Food processing industries

- Rubber and plastics industries

- Publishing and print industries

- Metal fabrication and finishing plants

- Paper industries

- Textile industries

- Natural gas processing plants

- Crude oil extraction and processing industries.

- Chemical Industries

- Plywood and Laminates

- Confectionery

Advantages of Thermic Fluid Heaters

- High Capacity Heating System

- Fully automatic unit – Maintains the desired temperature of the thermic fluid

- High System Efficiency – Reduced operating cost.

- Best applicable for High-Temperature Heating

- Can attain temperatures upto 300 o C

- Minimum site work and ease of installation

- Can operate on the variety of fuels as per local availability

- Failsafe design and dependable safety instruments

- Rugged design and superior construction

- High flow rate ensures the higher life of thermic fluid and heater coil

- Backed by prompt and efficient after sales service

- Deaerator/Expansion Tank Integral Arrangement type

| Business Type | Manufacturer, Exporter |

| Number Of Flower | Automatic |

| Material | Stainless Steel |

| Application | Liquid Boiling |

| Availability | As Per Designed |

| Country of Origin | 380V |

| Driven Type | Electric |

| Usage | Industrial |

| Capacity | 1 TPH to 6 TPH standard design; Customized up to 36 TPH |

| Pressure Range | 10.54 kg/cm2 to 21 kg/cm2 and abov |

| Fuels | HSD, LDO, Furnace Oil, Natural Gas, LPG, Dual Fuel option |

| International Standard | ASME. TEMA, ASHRAE, IBR, ASME-U-STAMP & R -STAMP |

Offered with high efficiency, monobloc or duo bloc burner.

Burner designed for easy maintenance and adjustments.

Oil heating and circulation system provided to accumulate excess fuel oil flow.

Highly durable and cost-effective performance achieved.

High purity steam generation reduces fuel costs.

Air preheater, Economizer and other accessories can be added to increase efficiency and lower operating costs.

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Automatic |

| Application | Industrial |

| Color | Available In Many Colors |

| Packaging Type | Wooden Box |

| Voltage | 440 V |

| Powder | 5-10 Kw |

| Warranty | 1 Year |

| International Standard | ASME. TEMA, ASHRAE, IBR, ASME-U-STAMP & R -STAMP |

| Weight | As per design |

Energy Plant is a unique solution from Thermax which offers multiple heating media such as Steam, thermal oil and Hot gas through highly efficient system with thermal efficiency more than 94%.

This system helps to minimize cost and maximize the operating efficiency. We have capability of supplying Energy Plant up to 97 MW.”

| Business Type | Manufacturer, Exporter |

| Type | Fin Tube |

| Material | Metal |

| Size | Standard |

| International Standard | ASME. TEMA, ASHRAE, IBR, ASME-U-STAMP & R -STAMP |

| Usage | Industrial |

| Surface | Polished |

| Weight | As per design |

DESIGN FEATURE