Ankleshwar Gidc, Gujarat

- GST NO. : 24ACNPC1767D1ZW

Mobile : View Mobile Number

| Business Type | Manufacturer, Exporter |

| Catalog | |

| Other Components | RADIAL DIFFUSER SYSTEM |

| Type Of Plant | Stratified Chilled Water Thermal Energy Storage System |

| Click to view more | |

Product Details

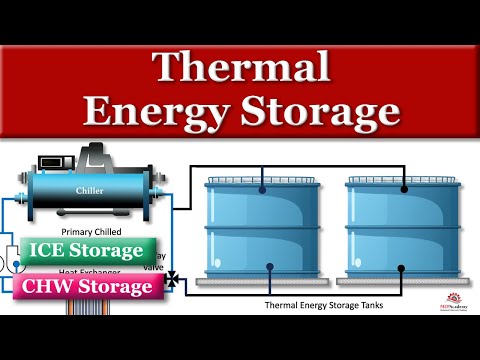

Thermal Energy Storage System (CWTES). This system utilizes only the sensible heat of water for cooling energy storage in a chilled water storage tank and discharges the stored coldness for air-conditioning during the on-peak time.

The key technology of CW Storage system is the diffuser design which ensures thermal stratification of chilled water and warm water by density difference. FITZER’s technology is the state of the art technology which is recommended in ASHRAE’s design guide. They have a long history of installation around the world including U.S.A., Japan, Korea and middle-east Asia.

Some key features of Chilled Water-Thermal Energy Storage Cooling:

Lowest initial investment cost

30-40% energy saving by utilizing conventional chillers whose

Efficiency is higher than low temperature chillers

Simple system with easy controls without additional heat

Light in weight compared to Si-Br.

Exchangers and less equipment

Efficiency of discharging coldness is very high

Easy to convert conventional system into CWTES system by

Adding only chilled water storage tank

Convertible to heating purposes

Environmentally friendly system free from brine

Storage water can be utilized for fire-fighting in emergency

What Is a Stratified Chilled Water TES System?

A Stratified Chilled Water TES System stores cooling energy by leveraging the sensible heat capacity of water. It uses a large insulated tank where chilled water and warm water are separated by density, forming distinct thermal layers—a phenomenon known as thermal stratification.

This stratification allows the system to charge (store cooling energy during off-peak hours) and discharge (release cooling during peak demand) efficiently, reducing energy costs and improving chiller performance.

⚙️ How It Works

The system operates in two main cycles:

Charging Cycle: Chilled water from the chiller enters the tank through bottom diffusers, gradually replacing warm water. The cold water settles at the bottom due to its higher density.

Discharging Cycle: Cold water is drawn from the bottom to meet cooling demand, while warm return water enters the top, maintaining stratification.

Diffusers play a critical role in minimizing mixing between layers, preserving the temperature gradient.

🧊 Types of Thermal Energy Storage Systems

There are several TES configurations, but stratified chilled water systems are favored for their simplicity and cost-effectiveness.

Other types include:

Diffuser Types in TES Tanks

Diffusers ensure smooth water flow and maintain stratification. Common types include:

Radial Disk Diffuser: Recommended by ASHRAE, this design spreads water evenly across the tank radius, minimizing turbulence. Ideal for large-scale TES systems.

Pipe Diffuser: Uses perforated pipes to distribute water; simpler but less effective in maintaining stratification.

Multiport Diffuser: Features multiple outlets for controlled flow; used in customized tank designs.

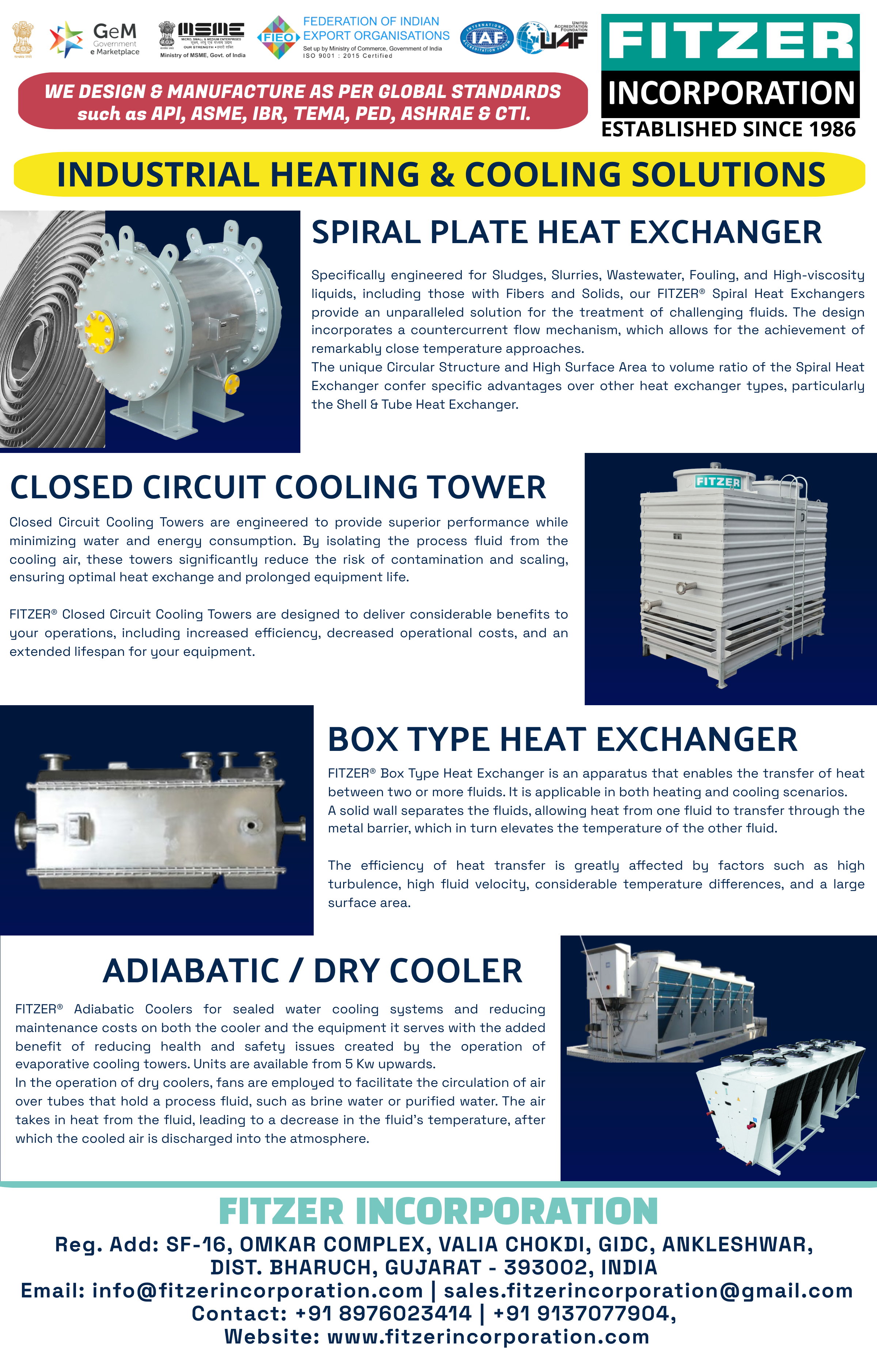

FITZER: Engineering Excellence in TES Systems

FITZER is a trusted name in the design and manufacturing of Thermal Energy Storage Systems, including stratified chilled water TES tanks. With in-house engineering and fabrication capabilities, FITZER delivers:

Custom-designed TES tanks for industrial and commercial applications

Precision-engineered radial disk diffusers

Seamless integration with existing HVAC infrastructure

Solutions aligned with ASHRAE guidelines and global best practices

Whether you're planning a new cooling system or upgrading an existing one, FITZER ensures high performance, reliability, and energy savings.

📈 Why Choose Stratified TES?

✅ Reduces peak energy demand

✅ Enhances chiller efficiency

✅ Enables load shifting

✅ Supports sustainable cooling strategies

Ready to revolutionize your cooling system? Connect with FITZER (INDIA) to explore tailored TES solutions that meet your operational and environmental goals.

Working Diagram

Looking for "Thermal Energy Storage System" ?

Explore More Products

Our Blogs