Ankleshwar Gidc, Gujarat

- GST NO. : 24ACNPC1767D1ZW

Mobile : View Mobile Number

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Stainless Steel |

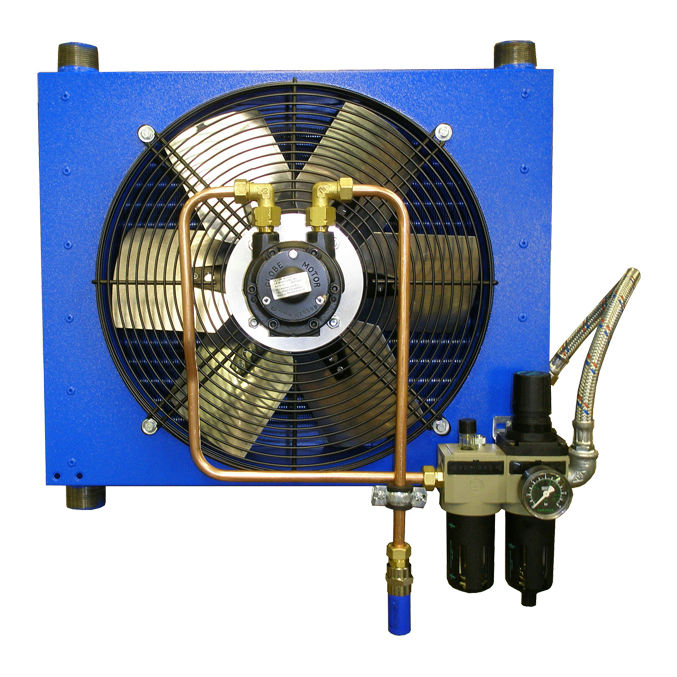

| Air Flow | 200 Scfm |

| Usage | Industrial |

| Click to view more | |

Product Details

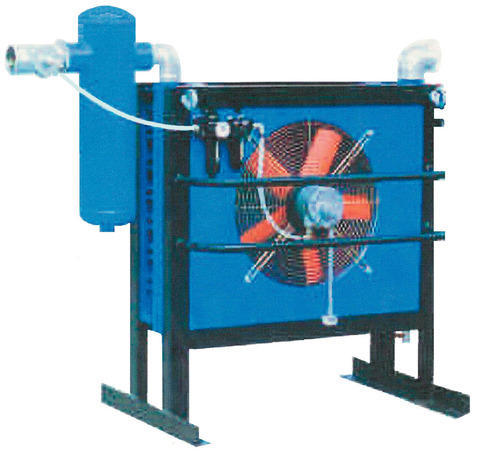

After cooler:

Water or moisture is not desirable in the transmission lines of an air compression system. Water carried through the lines washes away lubricating oil from the tools the compressed air is running. This causes the tools to operate sluggishly & increases the need for maintenance. The effect is compounded in high speed tools, where wearing surfaces are limited in size & excessive wear reduces efficiency by creating air leakage.

Further problem results from the decrease of temperature caused by sudden expansion of air at the end. This low temperature creates condensation, which freezes around port and valves & impairs efficiency. These conditions can be minimized by removing the moisture from the air directly after compression, before the air enters the distribution system.

The compressed air discharged from compressor is hot. Compressed air at these temperatures contains large quantities of water in vapor form. As the compressed air cools this water vapor condenses into a liquid form. As an example if an after cooler is not used, a 200 scfm compressor operating at 100 psig introduces 45 gallons of water into the compressed air system each day.

Functions of compressed air after coolers

-

Cool air discharged from air compressors via the heat exchanger

-

Reduce risk of fire (Hot compressed air pipes can be a source of ignition)

-

Reduce compressed air moisture level

-

Increase system capacity

-

Protect downstream equipment from excessive heat

Looking for "After Cooler" ?

Explore More Products

Our Blogs