Ankleshwar Gidc, Gujarat

- GST NO. : 24ACNPC1767D1ZW

Mobile : View Mobile Number

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Stainless Steel |

| Number of Fan Blades | 3, 4 |

| Usage | Industrial |

| Click to view more | |

Product Details

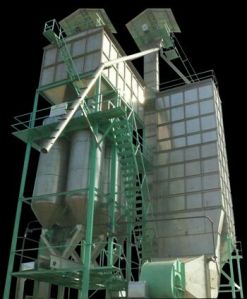

Inter cooler:

Most industrial compressors operating today are a multistage design. To optimize the cost of compressing gases it is popular to use multi-stage industrial compressor. When the Air compressor compresses air, heat is generated this causes the air to expand requiring an increase of horsepower for further air compression. If we remove the heat generated by compressing air, the total horsepower required for addition air compression is reduced up to 15%. For a multi stage compressor is to cool the gas between compression stages. Thus the role of the compressor intercooler is to provide colder, dryer, denser air to the next stage of compression. In addition to inter stage coolers, the compressor's final discharge is usually routed through an after cooler, which also provides colder and dryer gas to the end use point.

We provide Intercooler to suit compressor mounting by maintaining critical nozzle distance, as well as side mountings with volume bottles to avoid pulsation.

EFFICIENCY

Moisture Separator are largely used for the separation of coarse mist (or spray) from gases and vapors. A limit drop size (Dp) is used to characterize them and it is defined as the smallest particle which can be removed to an extent of 99%.

PRESSURE DROP

Due to the large percentage of the cross section available for gas flow, the pressure drop in a vast majority of applications is less than 250-500 mm WC. As mentioned above, for high efficiency applications, a larger pressure drop is to be expected.

.

|

Thermal Calculation are done on the based on suction condition

|

|

|

Looking for "Inter Cooler" ?

Explore More Products

Our Blogs